#Product Trends

CNC cutting machines

In some sectors, cutting foam, textiles or leather is at the heart of the business...

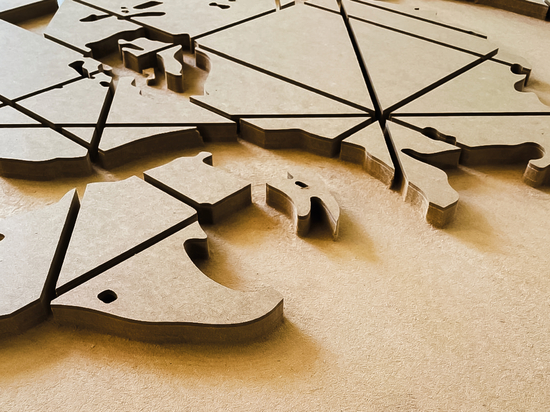

In some sectors, cutting foam, textiles or leather is at the heart of the business, but it can quickly become a repetitive or restrictive task. That's why KMSYSTEM has been developing and manufacturing numerically-controlled machines for many years to meet the needs of these sectors. Whether you're a saddler in the equestrian, automotive, furniture or decoration sectors, we'll be able to meet your requirements!

Our little extra is that our CNC machines are made to measure in our workshop in France and can be adjusted to your premises (no need to move). Depending on your needs and/or constraints, we can adapt the functionality of the CNC.

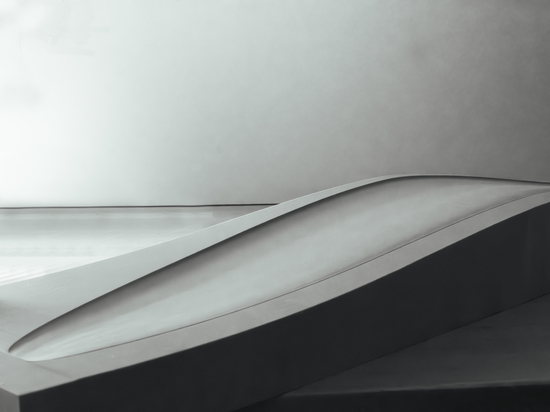

Thanks to our electrospindle, which is driven by a brushless motor, it is very quick and easy to change tools according to production needs. What's more, many tools can be nested on it. Whether it's vibrating knives or rotating knives. Our best sellers are the vibrating knives with a maximum length of 110mm, which can be used to cut many different materials! The materials can be hard, thick, soft or thin, and with the power of the brushless motor and martyr belt, you'll save non-negotiable amounts of time thanks to this automation. The best thing about all this, and the most important thing to remember, is that the result is just as beautiful and precise at the end of your cut.

Cutting foam or composite materials such as fibreglass generates a lot of waste and residue. We've thought of everything! Our machines can be fitted with a hoover to keep them clean for longer. In addition to the martyr mat, which limits vibration and reduces blade wear, a vacuum table can be fitted to the CNC machine, helping to immobilise the material during cutting.