#Industry News

Automated magnetizing station

V-shape (single and dual barrier) rotors - Continuous skewed or step skewed rotors

Rotor external diameter range: 100-200 mm

Rotor lamination height range: 50 – 200 mm

V-shape (single and dual barrier) rotors

Continuous skewed or step skewed rotors

Magnetic material: NdFeB sintered magnets

___

Requirements: full magnetization and measurement of rotors

___

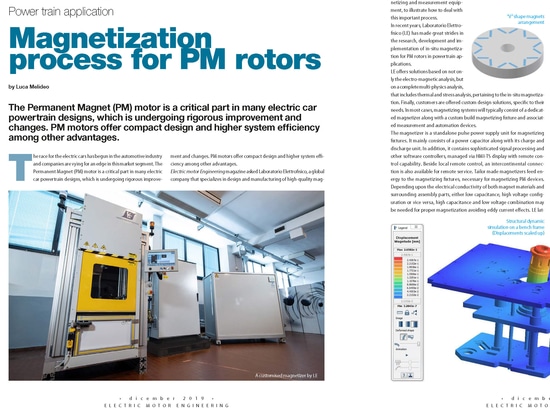

Amongst other applications, LABORATORIO ELETTROFISICO is focusing on the development of magnetizing and magnetic measuring solutions for e-mobility, in particular for powertrain applications. The main challenge is to achieve the best magnetization with reliable industrial equipment. LABORATORIO ELETTROFISICO is the leading company in this field, providing complete magnetizing stations with integrated handling systems.

Magnets are being continuously improved to achieve higher performance, and our magnetizing solutions can meet any customer’s requirements.

Our equipment is used to magnetize the rotors in powertrain motors. It is essential to note that powertrain rotors are heavy, and, when magnetized, the attraction force to any piece of steel makes the rotors difficult to handle. Thus, it is best to move them mechanically using a servo system. Our company also designs and manufactures handling stations. We mainly use robots or electric axes to position the rotors precisely and safely on the magnetization head and then to take it away once it is magnetized.

We met the challenge to achieve the highest quality for step skewed magnetization, reaching the goal of fully saturated magnets with our high-efficiency devices. We satisfied our customers’ requirements for low torque ripple and a high resistance to demagnetization in the degauss condition. Now we are working to realize the highest reliability and the fastest duty cycle, since our equipment is being used in factories.

We are continuing to develop mass production equipment that can be used to magnetize permanent magnet rotors. Our focus is on high cooling efficiency and optimizing the slots current density. We use the latest generation of FE suites from different software houses, including optimization algorithms.

Each time you drive an electric car, remember that the low engine vibration due to the quality of the magnetization of the magnets in the motor is one of the reasons why you feel comfortable. This is true also for the electric power steering, the windshield wipers, the brakes, and the chair-positioning actuators.

We serve the most challenging industries: automotive, consumer electronics, aerospace, and wind power generators. Where there are permanent magnets to be magnetized, LABORATORIO ELETTROFISICO is the best choice for designing and manufacture competitive and very high-quality equipment, delivering unique solutions including magnetization, the measurement of the magnetic properties and the handling system.