#Industry News

The drying granulator BRC 25 complements the granulation range

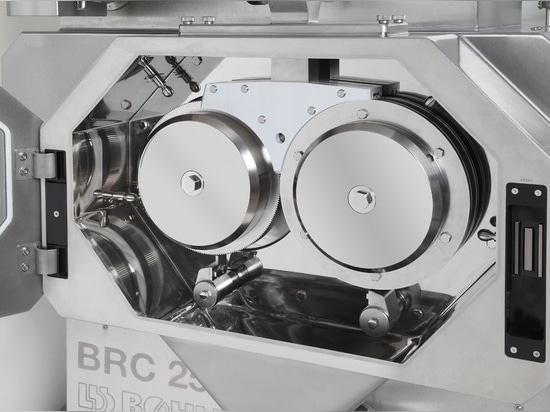

BRC 25 and BRC 100 compactor

With the BRC 25 roller compactor, which premiered at the Interpack 2014 in Düsseldorf, the machine builder L.B. Bohle Maschinen + Verfahren GmbH from Westphalia rounds off its offer of granulation solutions. The BRC 25 is the smaller version of the BRC 100 which

has already proven itself on the market.

Easy handling, continuous production and a small footprint are only some of the features of the roller compactor. Continuous dry granulation has been used in the pharmaceutical industry for decades. An advantage of the dry granulation process is that, in contrast to classic wet granulation, no energy-intensive drying processes are needed.

Therefore, customers will be able to invest less in machines and production rooms, resulting

in lower costs per batch. In addition, the operating costs are reduced as there is no additional power consumption for drying. With the compacting process, high material throughputs are

possible. All of this results in having one machine that can produce different products

and batch sizes.

The concept of the BRC: In the roller compactor, powders are processed to free-flowing granules. The aim is to process a granule with defined density or porosity for immediate pelletizing after compacting.

The powder is compacted between two rollers with specified gap widths between 1 and 6 mm. The impact on the rollers as well as the gap width is monitored via sensors. All data are integrated into a control circuit to ensure a continuous process quality. The electro-motor drive is essential for ensuring very precise and fast control of the process.

The chopper unit below the compacting rollers processes flakes into a granule at a defined granular size. The unit is equipped with a conical sieve with replaceable inserts for different

particle sizes.

Through target research and development, the BRC dry granulator technology

has been tailored to meet customers’ requirements. Thus, the BRC especially fulfils all specifications regarding ease-of-use, targeted control, cleaning and hygienic design.

Furthermore, the BRC requires extremely low maintenance and maintenance time as hydraulic technology was abandoned entirely. Cleaning for a product change can be implemented within two hours. This is not only due to the WIP equipment included as standard, but also to the easily dismountable components.

During the development of the BRC series, Bohle engineers paid attention to make the scale-up of BRC 25 to BRC 100 as easy as possible. This is ensured through the identical roller geometry and control in both machines. The dry granulators of the BRC series

are available in both service centers in Germany and the USA for test runs.