#Product Trends

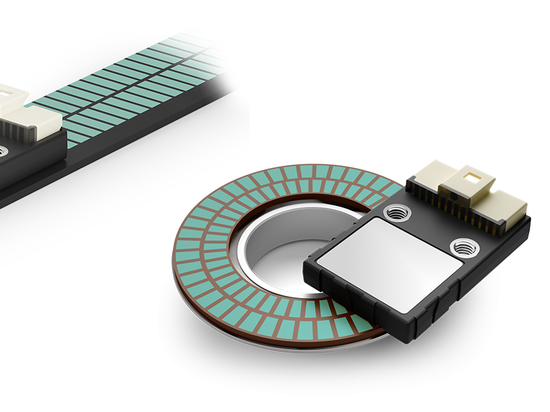

MIK36 and MSK36 bearingless encoders for rough jobs

MIK36 and MSK36 are shaftless and bearingless encoders capable of reliably and safely withstanding the most aggressive environmental conditions.

MIK36 and MSK36 are shaftless and bearingless encoders capable of reliably and safely withstanding the most aggressive environmental conditions. They are available in both incremental and absolute versions.

• Heavy-duty rotary encoders designed with separate rotor/stator

• Bearingless, shaftless, robust construction

• Non-contact, wear- & failure-free operation

• IP67 / IP68 protection with sealed electronics

• Perfect for rough applications

• Incremental version, resolution up to 20,000 PPR

• Absolute version, SSI interface, resolution up to 18 bits

MIK36 and MSK36 from Lika Electronic are shaftless and bearingless encoders designed for applications in aggressive environmental conditions. They offer a rugged measuring system free of moving parts, contact, friction, and wear and are available in both incremental and absolute versions.

They offer a separate rotor/stator design. The combination of a stainless steel rotor and integral magnet with a completely separate sensing circuitry (stator) increases the toughness and reliability of the encoder. The magnet assembly has a 6 mm (0.24”), 8 mm (0.31”), or 10 mm (0.39”) bore for installation in the output shaft of motors, actuators, or drives. The magnet and the sensing element are independent and work without any contact and mechanical connection to each other. This fully prevents shocks, vibrations, mechanical stresses, and eddy currents to be transmitted from the rotating shaft to the electronics. Furthermore magnetic scanning is insensitive to dust, dirt, oil, and liquids while the absence of wearable parts such as bearings allow for longer service life as well as greater efficiency and signal transmission safety. Thus there is no cause for concern about bearing wear, shaft loading or mechanical overheating.

In addition the robust and compact enclosure ensures a protection rate up to IP68 with sealed circuitry. These properties make the encoders exceptionally well suited for the harshest industrial environments and the most severe applications including mining and oil field equipment, steel mills, marble, stone, and glass working machinery, utility vehicles, and construction equipment.

MIK36 incremental encoder provides up to 20,000 PPR and generates digital signals (AB0, /AB0) through NPN, Push-Pull, and Line Driver output circuits. The max. counting frequency is 1.2 MHz.

MSK36 singleturn absolute encoder can reach a resolution up to 18 bits (262,144 cpr). The absolute information is provided through the SSI interface in Binary or Gray code, with counting direction and zero setting inputs.

Both axial and radial cable and M12 connector options are available.

Reverse polarity and short circuity protections further increase the safety level.