Website:

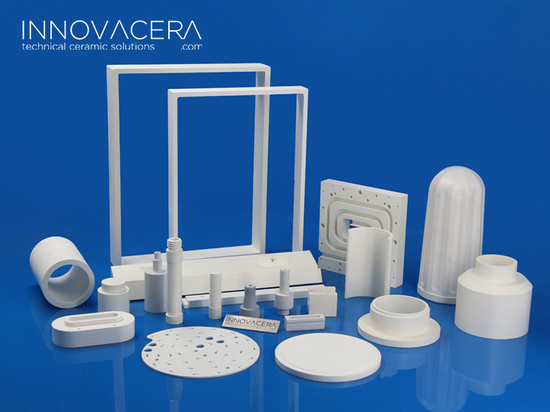

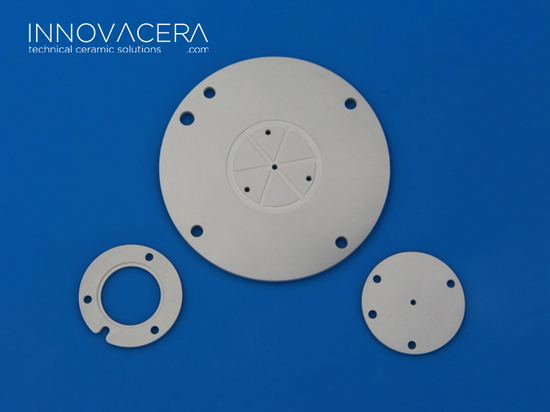

Xiamen Innovacera Advanced Materials Co., Ltd

Website:

Xiamen Innovacera Advanced Materials Co., Ltd

Group: INNOVACERA

Xiamen Innovacera Advanced Materials Co., Ltd company News and Trends items

228trends

Localization Map

Remove all