#Product Trends

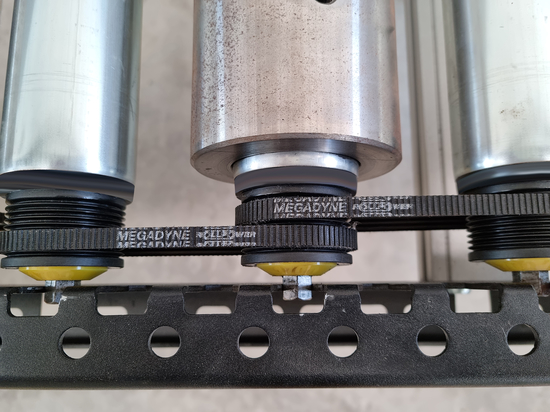

Megadyne Belts for Roller Mill Machines

Roller Mill Machines: Major Challenges

Roller mill machines are used in food processing industries for grinding grains to a variety of powders (including flour) and chemical products. They operate in harsh conditions and are exposed to extensive abrasion, heat and wear. The plants need to operate smoothly and the risk of any potential breakdown needs to be eliminated. The roller mill machines are thus working for long hours with no unpredicted downtimes.

Due to the above circumstances, the belts used in roller mill machines are put to the ultimate test. They need to face such problems as tooth jumps, increased power transmission within a limited amount of space and high loads, dusty and high temperature environment which may lead to pulley wear and belt damage.

Megadyne Roller Mill Belts

In response to the challenges of this specific food sector, Megadyne has come up with a variety of roller mill belts. They are available in the following range:

● Synchronous with PV back - the most powerful solution, applicable everywhere slippage and high power are required. The Synchronous side is available in either RPP, HTD or STD profiles, and the ribbed side in either PV-K or PV-L profiles.

● Double Sided Synchronous - the standard solution, available in either RPP or STD profiles. They can be manufactured in different structures: standard, Silver or Gold.

● Double Sided Poly-V - perfect for slippage, but at the same time significantly reducing the noise level. Belts are available in either PV-K or PV-L profiles. The special design increases contact surface and absorbs sudden spikes and blockages.

5 Major Advantages of Megadyne Roller Mill Belts

The major advantages of Megadyne roller mill belts include:

1. Smooth and powerful drive. The belts (double toothed belts apart) provide the ability to slip when blocked or overloaded. They minimise the risk of possible breakage. The performance is vibration-free. Additionally, belts are resistant to heat and abrasion.

2. Reliability and durability. The technology makes use of high-breaking strength cords and belt teeth resistant to jump and shear loads. The solution is thus highly resistant to wear damage.

3. Efficiency. The belts are ideal for high-power transmissions and to maintain stable power transfer throughout the process.

4. Time-saving. Easy mounting and removal of the belts.

5. Reduction of downtime and less maintenance.

Contact Megadyne Experts

Megadyne understands the challenges of food processing industry. Roller mill machines are not an exception. Contact the company to help you choose the best power transmission option for your business. Customised products are available, too.

For more information, please visit Megadyne website and follow the news on Megadyne LinkedIn profile.