#Industry News

SHARK 332 RC KONNECT-ED IN THAILAND

Discover how, thanks to the collaboration with our local dealer, Mep managed to find the right cutting solution for a Thai service center.

Given the competitiveness of today’s market, in which the customer is assuming an increasingly central role, it is no longer enough to focus on the simple sale of a product but it is necessary to shift the focus to the after-sales service and all the services supporting the sales. Therefore, the after-sales service becomes a fundamental tool in order to establish an even more solid and loyal relationship with customers.

For us at Mep it is of primary importance to offer cutting-edge sawing machines that provide at the same time a wide range of services making machine operation, maintenance and servicing much easier.

This was the case of a Thai customer who decided to rely on our company thanks to the collaboration with our local dealer. The customer is a well-known national service center that cuts and distributes a wide range of ferrous materials - such as tubes, profiles and beams. He already had an Hydmech H-320A automatic horizontal band sawing machine, providing accurate 90° metal cutting, and he decided to contact our dealer in order to find the best solution for miter cutting.

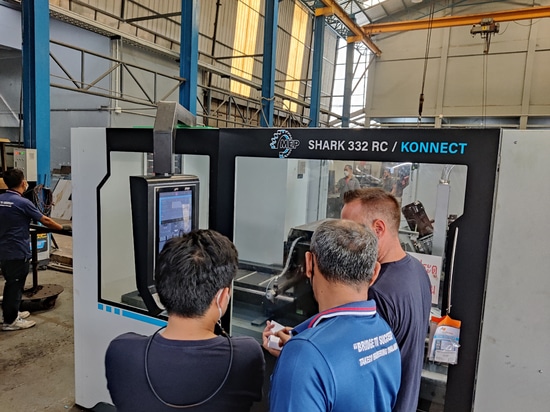

After a discussion with our dealer, we decided to recommend the automatic band sawing machine Shark 332 Rc Konnect, who then had the opportunity to see the machine in operation during some cutting tests made in our dealer showroom. The customer was impressed with both the performance and the double mitering programming system of the machine. At the same time, the features allowing the sawing machine to be remotely "Konnected" to our facilities played a fundamental role in the choice of this model because they facilitate servicing and reduce downtimes of the machine.

Why the automatic band sawing machine Shark 332 Rc Konnect

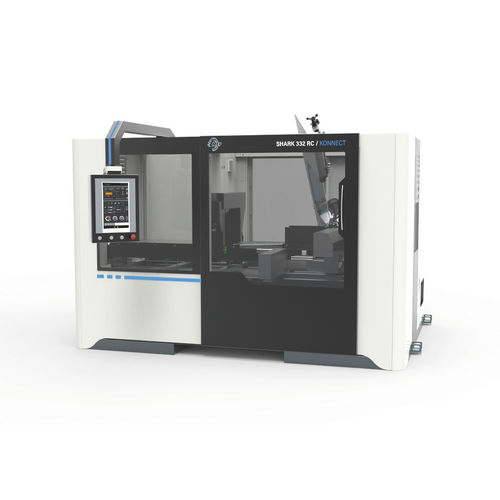

The Shark 332 Rc Konnect is an automatic electromechanical pivot band sawing machine with programmable automatic mitering to cut tubes, profiles and beams from -60° to + 60°. The double programmable mitering system maximizes safety and strength for reliable performance and an always efficient and smart manufacturing.

- Operator-free system: thanks to the auto-positioning of the saw head and vices as well as to the automatic handling of remnant and trim cut, the sawing machine functioning is completely automatized, thus minimizing the operator's intervention and setting times.

- Programmable automatic mitering of the saw head from -60° to +60° for symmetrical and asymmetrical cuts with servo motor that grants a precise control in speed, torque and positioning.

- The possibility to access to the after-sales service from remote through the main control of the sawing machine drastically reduces machine downtimes and service costs.

- Preventive maintenance, which is based on real working time of the sawing machine and its components, promptly informs about necessary maintenance, thus allowing to minimize passive working times.

- "Saw in the box" style ensures maximum operator's safety, while maintaining excellent visibility and accessibility of all working areas.

A big thanks goes to our Thai dealer for the work done during the sales process and for the excellent after-sales service provided to its customers. It is always a pleasure to see that our long-time collaborators agree and share our visions so that we can grow and improve together. We also want to thank the customer for the full trust in our cutting solutions: meeting the expectations of our customers and maintaining their trust over time are two main topics for our company.