#Product Trends

VALVES SERIES 70 SAFE AIR®

Starting from the robust and reliable valves series 70, we have added a

few distinctive features, such as the presence of a valve status diagnostic

system and the creation of a double communication channel

guaranteeing redundancy of the architecture.

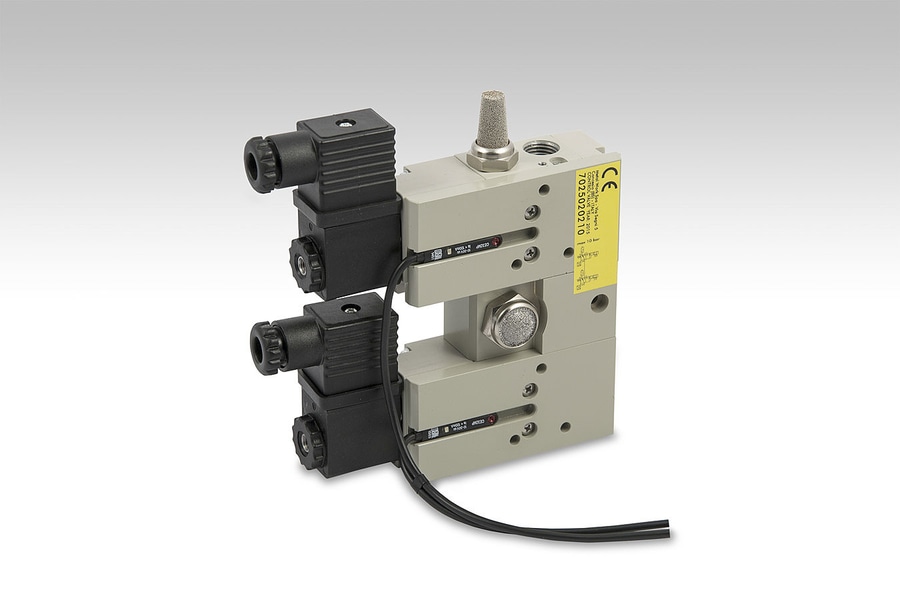

The simplest version is obtained from a pneumatically-operated 3/2

monostable valve. It is well known that when this type of valve is in the

idle state (coil de-energized), port 1 is not connected to the downstream

pneumatic circuit and port 2 is on relief; when the valve is operated (coil

energized), port 1 is connected to port 2. When the coil is de-energized

again, the valve is returned to the idle state (and hence port 2 relieves)

by means of a spring that returns the spool to the home position.

In the event of a failure, the spool may remain in the actuation position,

even when the coil is de-energized, thus leaving port 2 pressurized.

To offset this problem, we have added a Hall-effect sensor that reads the

spool position. This means that when the valve is deactivated, the sensor

is in the ON state, when the valve is activated, the sensor is in the OFF

state.

A status in which the sensor is OFF state and the coil de-energized indicates that there is a problem.

To reduce the probability of risk during plant maintenance, the manual actuator mounted on the electric control is the monostable type.

The sensor inside the valve is available in the standard version with a 2.5m three-wire cable (standard or ATEX certified) or with an M8 connector

and 300 mm cable.

This valve, which is available in sizes 1/8”, 1/4” and 3/8”, is a category 2 component, according to ISO EN 13849, and is suitable for use in safety

circuits up to PL = c.

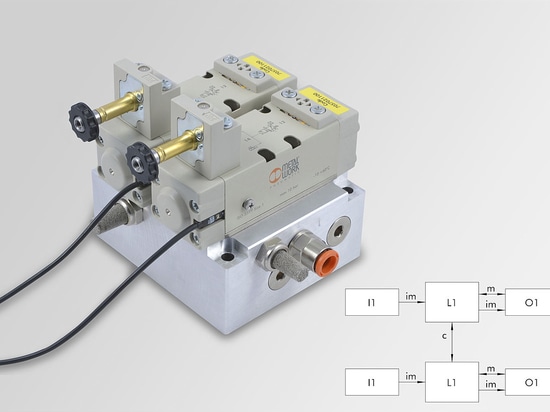

For applications requiring higher performance levels, we have also develop a double-channel version (redundant) that requires the use of two valves

series 70 with a monitored spool arranged so that port 2 of valve 1 is connected with port 1 of valve 2. If just one of the valves de-energizes, port 2

relieves, so, even if one of the two spools remains blocked, the other guarantees relief of the compressed-air circuit. In this case, too, the presence of

spool position sensors can be used to monitor the status......