#Product Trends

The new frontier in optical measurement for the shopfloor

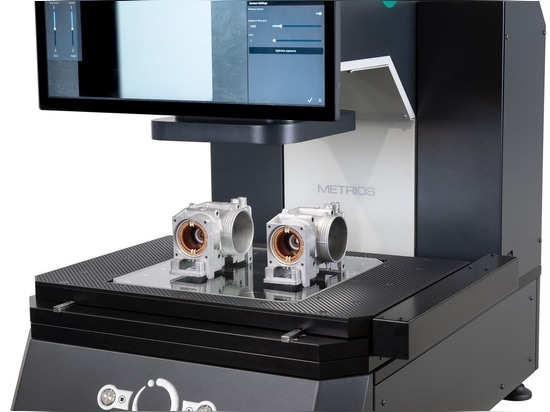

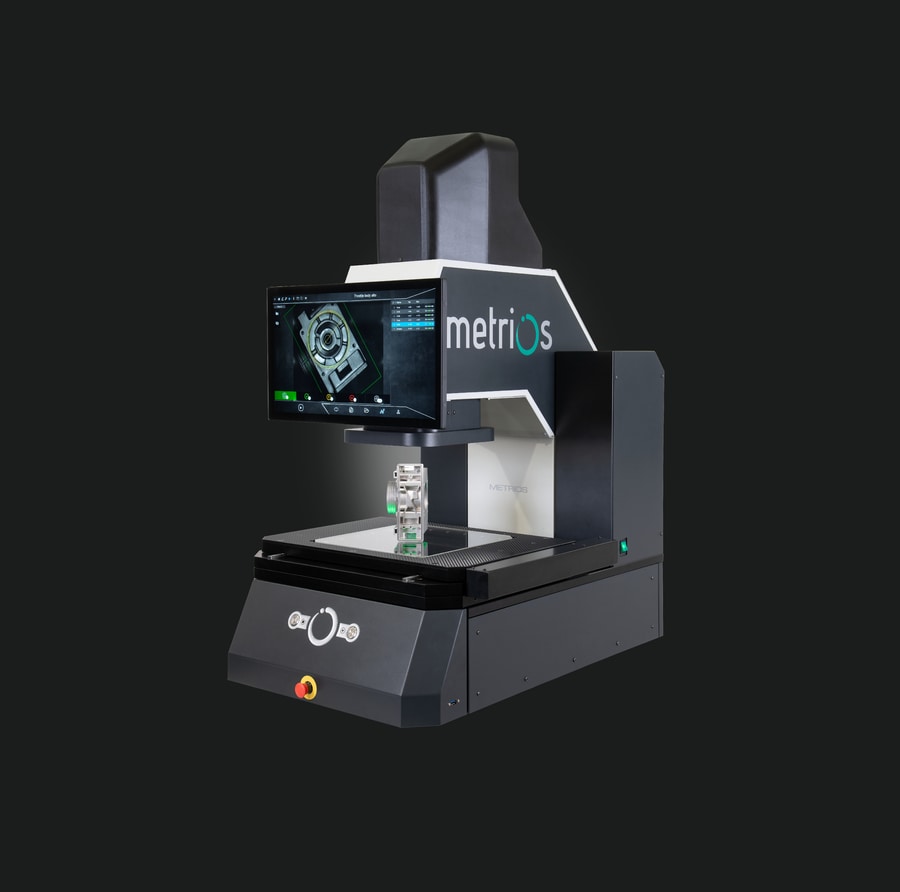

Welcome Metrios 332

In the machining industry, every detail is crucial. Using reliable and precise tools in your production process is vital to guaranteeing the quality of your end products.

To meet this requirement, Metrios measuring systems were developed.

The Metrios range provides a variety of models with different levels of precision, making it an ideal measurement solution for all types of components: from automotive, aerospace, and medical industries to semiconductors and microcomponents. With Metrios, dozens of dimensions can be checked in seconds through a single program, whether for individual or multiple parts.

The new Metrios 332 optical measuring machine was created in response to the need of component manufacturers who demand the precision of multi-sensor systems but also value the speed and ease of use offered by modern measurement technology. Metrios 332 combines all these qualities into one compact, powerful solution designed to operate in the shop floor.

Key features of the new Metrios model:

• A 300x300 mm X-Y measurement range with a spacious 200 mm part clearance;

• Supports parts up to 20 kg;

• A wide-field sensor for high-speed part detection and measurement;

• Ultra-high magnification sensor for exceptional precision able to detecting points in X-Y-Z even for the smallest details;

• Unique integrated lighting system.

The Metrios 332 system represents a significant advancement in the field of metrology, offering the convenience and speed of automatic optical measurement along with the precision of multi-sensor systems right on the shop floor.

It is an essential tool for workshops and manufacturers aiming to maintain high-quality standards and stay competitive in the market.