#Industry News

Cracking, opening, and closing handwheel-valves: how operators stay safe with torque management systems

Torque is not to be neglected when handling valves. Find out how to secure your operators with our torque management systems.

Cracking, opening, and closing handwheel-valves are common tasks to various industries. Some of the different workplaces that utilize handwheels are the power generation, water supply, petroleum refinement, railway, chemical and waste industries, and so one.

In order to help and protect operators and equipment of these workplaces, modec manufactures strong powerful portable valve actuators. Our priority being the operator’s safety, all our actuators come with torque management systems that prevent injuries.

A simple but effective torque management system comes with all our actuators

Our reaction arms, always included with our actuators, manage the torque properly so that the operator does not need to handle the torque by himself.

To understand what happens when you are operating a valve and the valve is completely closed or open, you need to have in mind what happens when you are drilling a hole with a drilling machine and the drill gets stuck. All the machine power will go through the machine, and you will have to support the force applied on the drill, in order to prevent the machine’s rotation.

Now transposing the same problem with a valve actuator, know that a drilling machine torque is 80 N.m and an actuator can reach up to 1000 N.m (that is 12,5 times more !). If you do not use an appropriate torque management system, the machine will injure you.

A range of torque management systems to fit best your application

We have thought and designed solutions for every different environment: no matter your application, you can find among our range the most appropriate torque management system.

Torque management systems are not just a matter of torque injuries prevention. They are also designed to be convenient for the user, comfortable and ergonomic. The main idea is that we want to provide a comfortable work position in order not to damage the wrist, elbow or back during the manipulation.

Through our years of experience among different industries, we found that most of the valves are installed in tricky positions, indeed, fluid lines are designed and built for the fluid line performance and not for the operator’s comfort. That is the reason why we designed valve actuation solutions with a wide range of torque reaction systems in order to help the operator to stay straight, and protect his body integrity during the operation.

Our torque management systems can hold the actuator in the correct position so that the operator doesn’t have to carry anything. Everything is in the correct position. You just have to press the trigger and you will open or close your valve without any effort and in the perfect position to protect your body and equipment.

Operate underground valves with our foot held articulated reaction arm

Here is an example to illustrate a tricky configuration you can face, we can have a look on the picture below:

While operating an underground valve and thanks to our torque management system, the operator stands straight on the ground level and he can operate underground valves in a healthy position.

Operate a handwheel safely on the ground level with our extension bar

In this example, you can see that with the extension bar (EB404), you can operate a handwheel on the floor level by standing on your feet.

No need to work in an uncomfortable position that will most definitely create professional diseases.

We also designed the BR002 torque management system that is a double reaction arm. Once it is correctly installed, you can operate the valve without any danger in both directions. The torque reaction arm will prevent a dangerous movement of the actuator when you end the manipulation.

Other accessories and options to keep operators safe during valve operations

Our torque management systems are compatible with all our range of options and accessories

Right angle head

Our torque management systems are compatible with all the different options in our range. If you need to use a right angle head to operate horizontally, you can plug the torque reaction arm on it, this is the same connection as the actuators heads. Everything has been designed to operate in a comfortable and safe position. On this picture, you can see a heavy duty actuator with the right angle head, to reach high torques.

To support the high speed and the high number of rotations, the global solution is heavy. However, you can assemble the accessories one after the other in order not to force during the solution assembly. When it is done, the weight of the tool and accessories is supported by the hand wheel. The operator only has to press the trigger to operate the valve. He stands in a comfortable and healthy position without any force to apply during the operation.

Self-centering adaptors

We designed a range of self-centering adaptors (SAXX) that prevents from bad movements. Thanks to its patented system, these adaptors clamp instantly onto the handwheel and the actuator automatically centres itself giving greater ease and efficiency. These adaptors remove injuries on the operator’s elbow and wrists.

Safer valve operations with torque limiters

Safety being our priority, we also manufacture torque limiters (they come in standard on our electrical actuators or in option on the other ones). Thanks to the torque limiter, you can set the torque you need in order to operate your valve. When you have reached the requested torque, the clutch will disconnect the motor and stop the rotation. It is a very safe solution to protect the operator but also not to damage the material. Each torque limiter we offer can reach a large range of torque. Thanks to this option you can use the same actuator on different valve or handwheel sizes, without any danger.

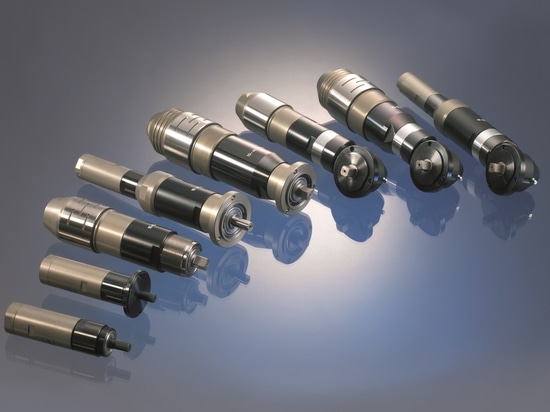

We manufacture different sizes of actuators, from the easy duty to the heavy duty. This offers the lighter possible solution available. If you have to operate low ranges of torque, (up to 70 N.m) you can use a light tool. You don’t need to buy a big and heavy tool if it is not needed.