#Industry News

Solutions for unloading wagons for bulk materials

Transport companies: Unload compacted bulk material from wagons quickly and efficiently, while reducing the number of operators on site. You do not own the trains and do not wish to invest in them? We have the solution!

Transport companies: Unload compacted bulk material from wagons quickly and efficiently, while reducing the number of operators on site. You do not own the trains and do not wish to invest in them? We have the solution!

Simplify railcar unloading

Freight trains carrying semi-liquid materials (cereals, sugar, etc.) are equipped with wagons with unloading hoppers. In order to empty these cars, many valve turns are required and the number of cars is often endless.

In order to find the perfect solution, Modec met with the major players in the transport sector. We first developed a system on board the train. However, with this solution, there were very strong constraints in terms of maintenance. Indeed, the motors of these on-board systems must be able to withstand maintenance-free for at least six years, subjected to bad weather, cold, heat, humidity, salt, etc. These motors must also be able to be disengaged to allow their manual operation. Finally, they must fit perfectly into the current mechanics of the wagon, without impacting its structure.

The engines we had developed met all these requirements. But, fixed on the wagon, they had to be financed by the train owner who did not want to make such an investment when his goal was to rent his train to the transport companies as long as possible. Transport companies did not want to pay for an on-board system on trains that they did not own.

The second solution was to build a motorized solution that remains on the dock. In this case, it belongs to the "port". But once again, the latter does not necessarily seek to invest in order to unload faster. They are looking for full activity and therefore do not seek to automate.

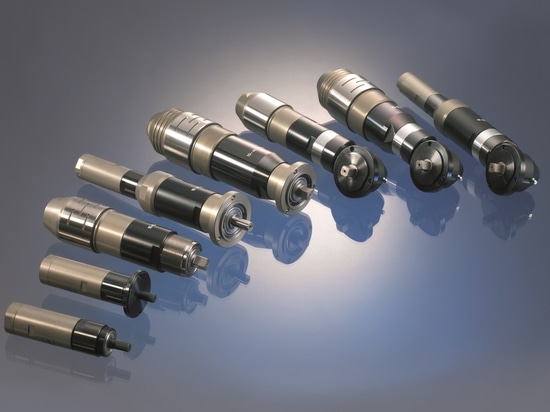

The ultimate solution is finally the portable valve actuator. It allows to go from valve to valve (therefore from wagon to wagon) and to open the hoppers. It is a more economical solution, because it is easy to implement, allowing companies that operate trains to be more efficient and therefore to requisition these trains for a shorter period of time.

The benefits:

-Increased benefits: With faster unloading times, you can move more materials, which represents additional revenue.

-Increased productivity: The use of products specially designed to be connected to the hopper valves allows you to move more materials with shorter unloading times. Easy to use: just take the tool out of the workshop and go to the platform. A quick and efficient implementation....

-Significant savings: Faster and more efficient unloading also means lower labour costs compared to the quantities of materials moved.