#Industry News

3 reasons to use pneumatic portable valve actuators for drinking water system operations

The use of a portable pneumatic actuator allows to improve the working conditions of drinking water system (DWS) operators

Drinking water system operators (DWS) are subject to strong physical constraints. Their job requires indeed important and repeated efforts for block valves actuation. With conventional tools, vibrations and jolts are likely to create serious injuries and work-related musculoskeletal disorders (elbow tendinitis).

In addition, opening or closing a valve too quickly on a pressurized system may cause a water hammer effect. This well known risk among DWS operators can have a major impact on the reliability of a water network. The resulting wear and damage can cause costly service disruptions in terms of service quality level and maintenance.

To avoid this inconvenience, the use of a pneumatic portable actuator is recommended!

Here is a concrete example of the advantages of using a portable actuator with a block valve on a drinking water distribution network.

This video emphasizes a simple and efficient system for manipulating block valves, even the most difficult ones, quickly and without effort!

The difference between the two situations, before and after the use of a portable pneumatic actuator, is clearly demonstrated.

1. Material safety

The opening and closing of the valve is done at a controlled speed and torque, ensuring its integrity and that of the network. Water hammer is no longer a risk.

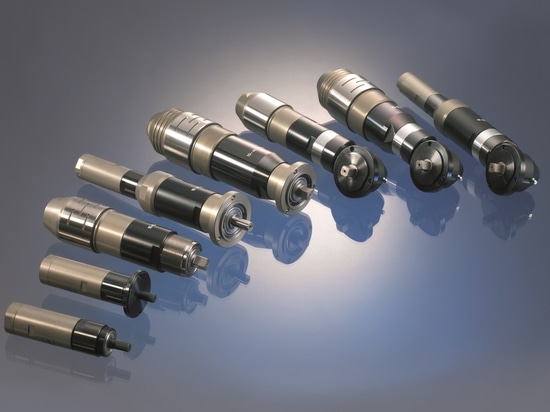

The ingenious design of portable actuators allows one to adapt their configuration to any particular situation.

2. Worker safety

After a quick installation of the portable actuator, we can see that the DWS operator doesn’t need to exert any effort. Installation and operation can be done by one person only.

Protected by his vehicle, the operator remains still during the maneuver. The risk of being in the way of traffic and potentially struck by a car is eliminated.

Portable actuators ergonomics is specially designed make them easy tools to use.

3. Time saving – productivity

As stated in the operator testimony in the video, the manual opening of a valve takes more than 15 minutes and is done with great difficulty.

With the portable pneumatic actuator, the opening is done quickly with full control of the speed and torque, but above all with real ease of use!

Hence, it creates a real advantage in operations planning as teams efficiency on the field will increase.

Already implemented in other industries such as petrochemicals or food processing, the use of portable pneumatic actuators is a very convenient solution for people involved in the water industry.