#Industry News

NETZSCH SPHERHO®

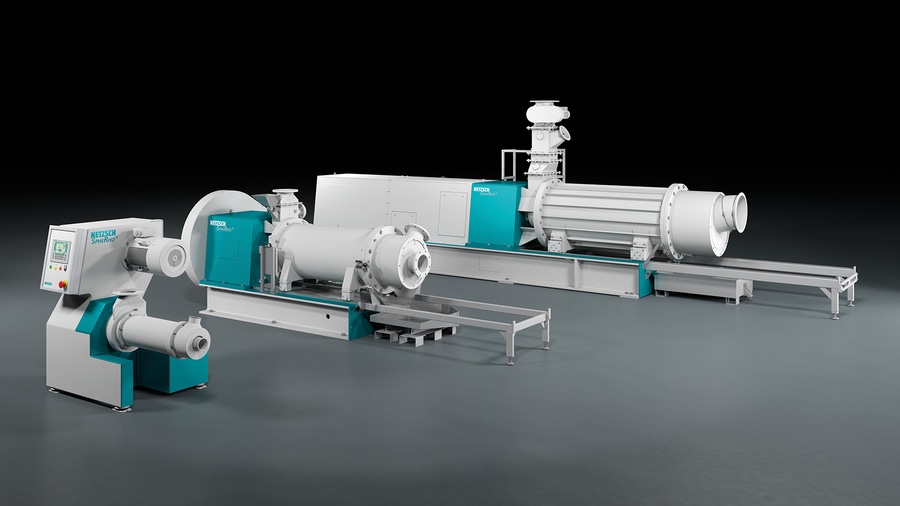

An Agitator Bead Mill for Dry Fine Grinding: NETZSCH SPHERHO® impresses with unique product advantages

NETZSCH is expanding its product portfolio with an agitator bead mill for the dry grinding of mineral and ceramic raw materials. The SPHERHO® impresses with very high product fineness and high throughput rates with low specific energy consumption.

Technology Leader in Wet and Dry Grinding

With its Business Unit Grinding & Dispersing, the NETZSCH Group ranks among the world’s market leaders in both wet and dry processing technology. For decades, agitator bead mills from NETZSCH have been successfully employed in a broad range of industries for the grinding and dispersing of suspended solids. Now the company has transferred this globally-proven technology from wet applications to dry grinding and, with the NETZSCH SPHERHO®, introduces an agitator bead mill with unique product advantages.

Extremely fine and very efficient

Unlike conventional bead mills, the NETZSCH SPHERHO® operates with very small grinding beads. This results in a higher stress intensity. In this way, ultra-fine grinding of even comparatively coarse feed product is possible with low energy input. In conjunction with the NETZSCH INLINESTAR, mineral fillers with finenesses of less than 2 µm are possible.

Compact Design

At approx. 400 kW/m3, the specific grinding chamber energy of the NETZSCH SPHERHO® is many times greater than that of conventional bead mills. This is reflected in smaller footprints and bases. Its simple, sturdy design allows for quick changeover of grinding media and agitator elements, making maintenance and service easier.

Unique and patented

A separation system developed and patented by NETZSCH makes it possible to use small grinding media in a dry agitator bead mill. This makes the SPHERHO® unique. NETZSCH has introduced the new mill at this year’s POWTECH in Nuremberg along with two other true world debuts: SMARTREMOVAL – an innovative hose replacement system that revolutionizes the exchange of filter hoses and baskets for Side Removal filters – and EPSILON – a totally new solution for producing homogeneous dispersions in an inline process with reproducible quality.