#Industry News

What is a Planetary Gearhead?

Take you to understand planetary gearhead

Introduction

Ever wondered what powers the precise movements in robots or the efficient operation of aerospace mechanisms? The answer often lies in a compact, yet powerful component known as a planetary gearhead. This article delves into the workings, types, benefits, and selection criteria of planetary gearheads, illuminating their critical role in modern machinery.

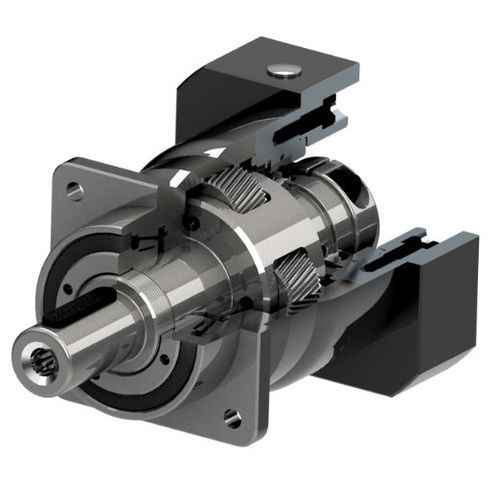

Understanding the Basics of Planetary Gearheads

At the heart of a planetary gearhead, also referred to as a planetary gearbox or planetary gear reducer, lies a highly efficient gearing system.

A planetary gearhead works in a somewhat similar with solar system. At its core is the ‘sun gear,’ which is the main driver. Surrounding the sun gear are several ‘planet gears’ that rotate around it, just like planets in our solar system. These planet gears mesh with both the sun gear and an outer ‘ring gear,’ which encircles the whole system. The planet gears are mounted on a ‘carrier,’ which holds them in place as they orbit. This finial is: 1. Reduce speed 2. Increase torque.

The true beauty of a planetary gearhead is its ability to distribute the load across multiple gears, which means it can handle a lot more torque than a single gear could. Also, because of its compact and symmetric design, it can fit into tight spaces and provide high power density—the ratio of power to volume.

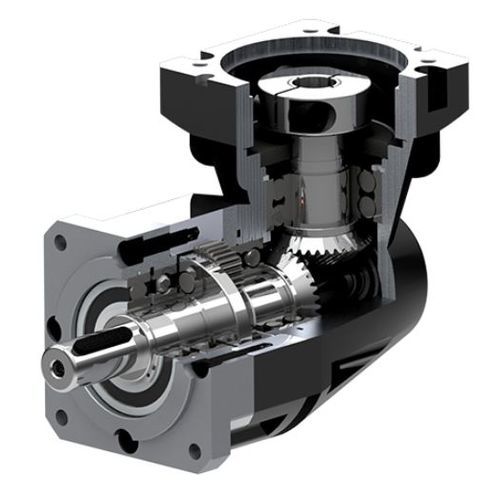

Types and Applications

Planetary gear box come in various forms, each designed to meet specific requirements. Standard, precision, and high-torque variants are the most common, catering to different industrial needs. From robotic arms requiring precision to heavy-duty machinery demanding high torque, the versatility of planetary gearboxes makes them a go-to solution across sectors like automation, aerospace, and robotics.

The Advantages Unveiled

Why opt for a planetary gear reducer over other types? The benefits are clear: unmatched efficiency, compact design, robust performance, and extended lifespan. These gearheads are engineered to handle high stress with minimal maintenance, making them ideal for applications demanding reliability and precision.

Selecting the Right Planetary Gearhead

5 steps select gearbox you need

Choosing a suitable planetary gearhead involves considering torque requirements, precision levels, size constraints, and budget. A planetary gearhead manufacturer can guide you through selecting a model that aligns with your application’s needs, ensuring optimal performance and value.

Conclusion

Planetary gearheads are pivotal in driving the efficiency and precision of modern machinery. Whether you’re into robotics or aerospace, knowing these components’ functions and benefits can greatly enhance your projects. It enriches your understanding and guides your design choices.For those looking to integrate planetary gearheads into their designs, reaching out to a reputable manufacturer is the first step towards unlocking their potential.

Contact us

Eager to explore how a planetary gearbox can enhance your project? Contact us today for expert advice and a comprehensive range of solutions tailored to your requirements. Let’s gear up for success together!