#Product Trends

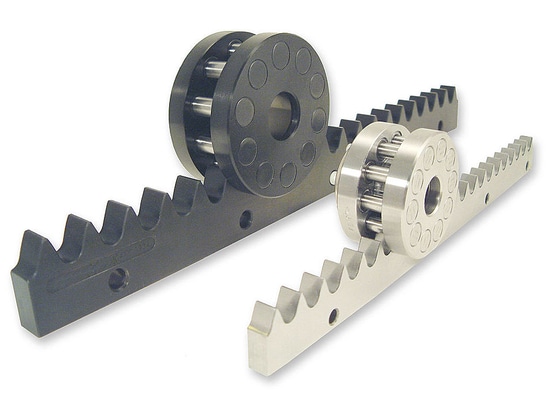

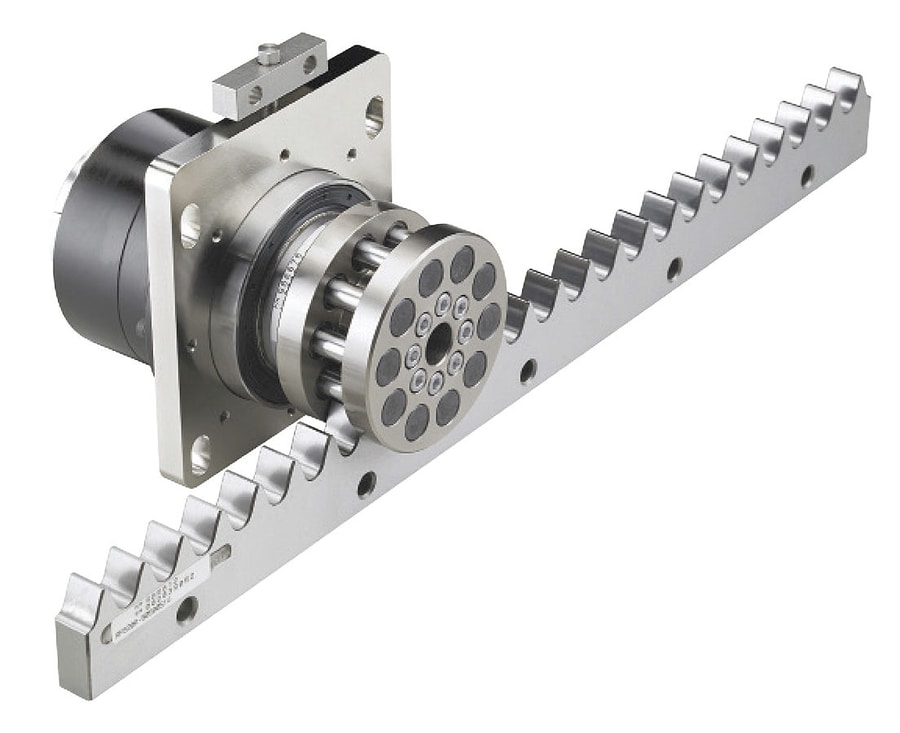

Roller Pinion System: An Alternative to Traditional Linear Drive Systems

Full lengths are around one meter in length and half-lengths around ó meter in length depending on tooth pitch. Shorter rack segments can be made by cutting the rack. Featuring positional accuracy up to 30, 50 and 80 microns, the RPS accommodates virtually any application''s precision requirement. Further, by offering diverse performance capabilities, engineers can optimize their performance/price ratio for a specific machine design. Typically, the Premium rack offers accuracy of 30 microns, while Standard, Universal and Stainless Steel Universal racks will feature positional accuracy of 50 microns and the Endurance rack is capable of positioning precision up to 80 microns. To transfer the positional accuracy to the following rack segments, a special tool was developed that uses the rack tooth profile to set the rack spacing rather than simply butting racks end to end. The alignment tool uses two teeth on each rack averaging out some of the transferred error. This small transferred error is ± each time and statistically trends to zero, so an infinitely long run would, in theory, have zero cumulative error. This allows runs of virtually any length without loss of system accuracy. In many cases, a linear encoder is no longer needed and the servo encoder can be relied on reducing cost and complexity. For the Full White Paper and Drawings, please see attached document.