#Product Trends

NGI DC electronic load in EV charging pile&module Test

With the continuous development of EV, the demand for charging piles is increasing. In the past, physical test methods through real electric vehicles were often used for charging pile test.

With the continuous development of EV, the demand for charging piles is increasing. In the past, physical test methods through real electric vehicles were often used for charging pile test. Now more and more manufacturers choose DC electronic load to test charging pile. However, during the test process, field engineers may encounter the abnormal situation of overcurrent protection of EV charging piles.When choose the CV mode of electronic load, and set the minimum charging voltage of the charging pile as the loading parameter value of the CV mode,it is gradually loaded to 700V, during the test,in order to stabilize the load at 700V as soon as possible, the current will increase faster. If the current overshoot time is long and the amplitude is large, it will lead to overcurrent protection of the tested charging pile product. In response to this problem, NGI N69200 series high-performance high-power programmable DC electronic load can solve it very well.

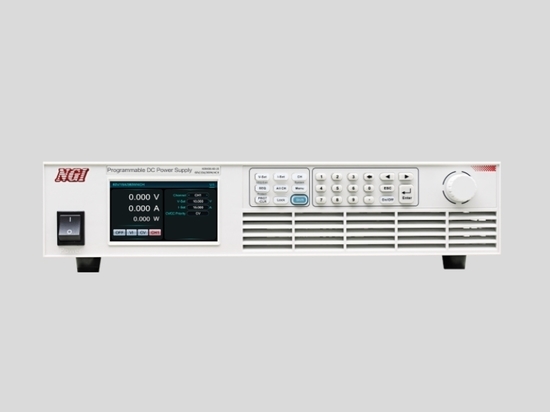

NGI N69200 series is a high-performance high-power programmable DC electronic load product with high reliability, precision and multi function. It offers 150V, 600V and 1200V voltage specifications, and the power of the standard 19-inch 3U chassis is up to 6kW.

Standard CV+CC mode: It can solve the problem that the charging pile cannot be started due to overcurrent in the test. With CV+CC mode, limiting current can be set at the same time of voltage pulling. When overcurrent occurs during the test process and the charging pile cannot be started, the engineer only needs to use the parameter setting of this mode to limit the CV loading and adjust the internal current to not exceed the overcurrent protection point of the charging pile, which can effectively solve the problem.

N69200 series support master/slave parallel connection,after parallel it can achieve actively flow equalization, when the load power demand increases, all the models with the same voltage specifications can be connected in parallel (master + master, master + slave) to achieve the required current and power. When using the N69200 series products, the user only needs to program the load current on the master load, and the slave load can be automatically allocated, which further simplifies the user's operation steps. 3U/6kW ultra-high power density, parallel power up to 500kW. After the parallel, all operations only need to be set on the master panel, and it will be assigned to the slave machine, which ensures high performance, easy maintenance and cost savings. At the same time, a variety of communication interfaces (LAN/USB/RS232/GPIB) are built in to facilitate users to remotely control the product and conduct various tests.

N69200 series products makes the test of charging piles more efficient and fast,with comprehensive protection functions and ultra-high precision measurement,so that N69200 series can meet the needs of engineers for various high-power test.