#Industry News

The role of exhaust insulation blankets in reducing heat loss and improving engine efficiency

The role of exhaust heat blankets in reducing heat loss and improving engine efficiency

Exhaust insulation blankets play a crucial role in managing heat within the exhaust system of various applications. This article explores how these blankets contribute to reducing heat loss and improving engine efficiency, leading to enhanced overall performance.

Heat Containment and Heat Loss Reduction:

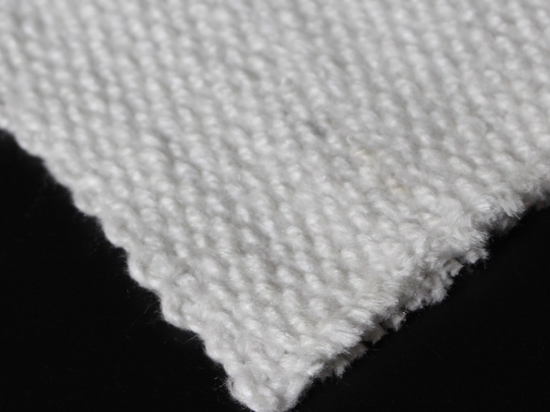

Exhaust insulation blankets are designed to tightly envelop exhaust components, such as manifolds, pipes, and catalytic converters. By effectively containing and insulating the heat within the exhaust system, these blankets minimize heat loss to the surrounding environment. This containment reduces wasted energy and heat dissipation, maximizing the thermal efficiency of the system.

Reduced Underhood Temperature:

Insulation blankets create a thermal barrier that prevents excessive heat from radiating into the engine compartment. By keeping the underhood temperature lower, they help maintain a cooler environment for sensitive components, such as electrical systems, hoses, and nearby fluid reservoirs. This preservation of lower temperatures minimizes the risk of heat-induced damage and extends the lifespan of these components.

Enhanced Exhaust Gas Flow:

Exhaust insulation blankets optimize the flow of exhaust gases by maintaining higher temperatures within the exhaust system. The blankets prevent heat dissipation, ensuring that the exhaust gases stay hot and flow more efficiently. This improved flow reduces backpressure, allowing the engine to expel exhaust gases more easily. As a result, engine efficiency is enhanced, leading to improved power output and fuel consumption.

Catalytic Converter Efficiency:

Exhaust insulation blankets have a significant impact on the performance of catalytic converters. By maintaining higher temperatures within the exhaust system, the blankets enable catalytic converters to reach their optimal operating temperature more quickly. This rapid heat-up enhances the converter's efficiency in reducing harmful emissions by promoting effective chemical reactions. As a result, exhaust emissions are minimized, contributing to improved engine efficiency and compliance with emission regulations.

Minimized Heat Transfer to Intake Components:

Insulation blankets help reduce heat transfer from the exhaust system to nearby intake components, such as air intake tubes and air filters. By limiting the heat transfer, the blankets ensure that the incoming air remains cooler. Cooler intake air is denser, resulting in improved combustion efficiency, increased power output, and enhanced fuel economy. Consequently, engine efficiency is improved, leading to a more effective utilization of fuel.

Prevention of Heat-Related Performance Degradation:

Excessive heat can lead to performance degradation in various engine components, including sensors, fuel lines, and wiring harnesses. Exhaust insulation blankets act as a protective layer, minimizing heat exposure and preserving the performance and longevity of these critical elements. By preventing heat-related damage, the blankets help maintain the engine's efficiency and reliability over time.

Conclusion:

Exhaust insulation blankets play a vital role in reducing heat loss from the exhaust system, optimizing engine efficiency, and improving overall performance. By containing heat, minimizing heat transfer, and preserving higher temperatures within the exhaust system, these blankets contribute to enhanced power output, reduced fuel consumption, and minimized emissions. Their role in preventing heat-related damage further ensures the longevity and reliability of engine components. Implementing exhaust insulation blankets is a valuable strategy for maximizing thermal efficiency and achieving optimal engine performance.