#Product Trends

Unveiling the Power of Heavy Duty Fiberglass Braided Sleeve

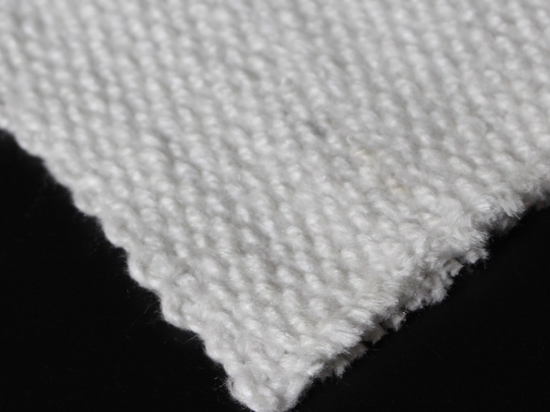

Fiberglass Braided Sleeve

With the growing demand for durable and resilient protection solutions in various industries, the heavy duty fiberglass braided sleeve emerges as a frontrunner. Let's delve deep into what makes this material the ultimate protective solution.

Benefits:

High-Temperature Resistance: Unlike conventional sleeves, heavy duty fiberglass braided sleeves can withstand extremely high temperatures, ensuring that underlying wires or hoses are safe from heat-related damages.

Durability: Crafted for tough conditions, these sleeves resist abrasions, chemicals, and other environmental factors, promising long-lasting protection.

Versatility: Suited for various applications, from automotive to industrial setups, the adaptability of these sleeves is commendable.

Key Applications:

Automotive: Perfect for engine bays where high temperatures are prevalent. They protect essential wires and hoses from potential damage.

Electronics: Power supplies and other components can heat up during prolonged usage. This sleeve ensures that heat doesn't compromise surrounding components.

Manufacturing & Industrial Machines: Machines often run for extended durations and require top-notch protection against wear and tear. Enter the heavy duty fiberglass braided sleeve.

Making the Right Choice:

While the heavy duty fiberglass braided sleeve is a game-changer, it's crucial to select the right fit for your needs. Consider factors like diameter, length, and specific environmental challenges when making your choice.

Conclusion:

The heavy duty fiberglass braided sleeve isn't just a protective tool—it's a peace-of-mind inducer. Whether safeguarding vehicle components or shielding wires in an industrial setting, its unmatched resilience ensures you're always protected.