#Product Trends

Polyester Multifilament and Polyolefin Filament: The Key Elements of Fabric Heat Shrink Sleeve

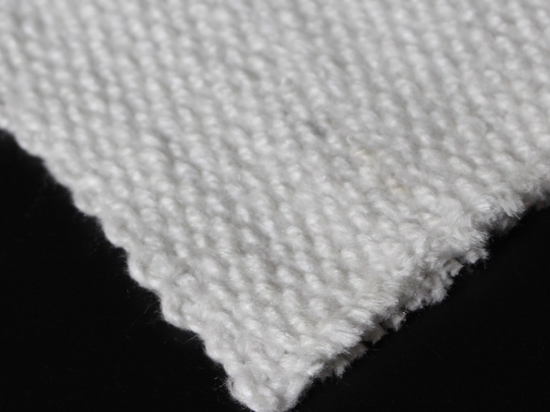

Fabric Heat Shrink Sleeve

Fabric Heat Shrink Sleeve is a remarkable protective solution widely used to safeguard cables, hoses, and wires in challenging industrial environments. At the heart of its exceptional performance lie two critical elements: polyester multifilament and polyolefin filament. Understanding the unique properties and characteristics of these key components is essential in comprehending the effectiveness and versatility of Fabric Heat Shrink Sleeve.

Polyester Multifilament: Strength and Durability

Polyester multifilament serves as a foundational element in Fabric Heat Shrink Sleeve, contributing to its strength and durability. Composed of multiple fine fibers spun together, polyester multifilament possesses exceptional tensile strength and resistance to tearing and abrasion. This ensures that the sleeve can endure harsh conditions and mechanical stress without compromising its protective capabilities. The high tensile strength of polyester multifilament reinforces the structural integrity of the sleeve, preventing it from fraying or deteriorating over time.

Polyolefin Filament: Heat-Activated Shrinkage

The inclusion of polyolefin filament in Fabric Heat Shrink Sleeve imparts its unique heat-shrinkable property. Polyolefin is a thermoplastic material that undergoes significant shrinkage when exposed to heat. This characteristic is essential in the installation process, where the application of heat causes the sleeve to contract tightly around the cables, hoses, or wires. The resulting custom fit provides a seamless and snug protective layer, enhancing the overall effectiveness of the sleeve in shielding against flames, abrasion, and other external hazards.

The Synergy of Strength and Shrinkage

The combination of polyester multifilament and polyolefin filament creates a powerful synergy in Fabric Heat Shrink Sleeve. The strength and durability of polyester multifilament ensure that the sleeve can withstand rugged conditions, while the heat-activated shrinkage of polyolefin filament enables a precise and secure fit around complex shapes and contours. This unique combination allows the sleeve to adapt to irregularly shaped cables or hoses, providing a custom protective layer that conventional rigid protection methods cannot achieve.

Versatility and Applications

The use of polyester multifilament and polyolefin filament in Fabric Heat Shrink Sleeve makes it a versatile solution suitable for a wide range of applications across diverse industries. From automotive and aerospace to marine and electronics, the sleeve finds application in environments where cables and hoses are exposed to flames, abrasion, and harsh elements. Its ability to protect critical components ensures enhanced safety, longevity, and reliability in various industrial processes.

Conclusion

Polyester multifilament and polyolefin filament are the key elements that make Fabric Heat Shrink Sleeve a superior protective solution for cables, hoses, and wires in demanding environments. The combination of strength and durability with heat-activated shrinkage ensures that the sleeve offers unmatched versatility, adaptability, and reliability. By leveraging the unique properties of these key components, Fabric Heat Shrink Sleeve becomes an essential asset in safeguarding critical electrical connections and fluid transfer systems across industries, setting a new standard in cable protection practices.