#Product Trends

Installing Fabric Heat Shrink Sleeve: A Step-by-Step Guide for Efficient Cable Protection

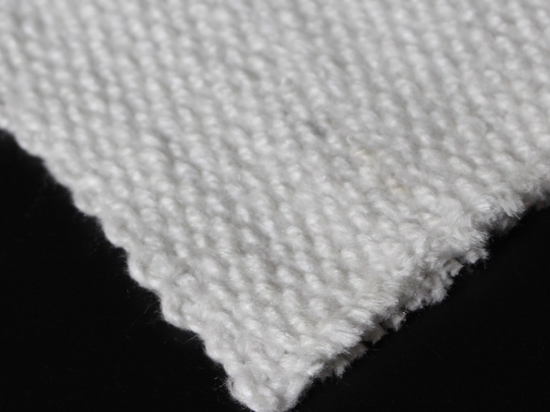

Fabric Heat Shrink Sleeve

Fabric Heat Shrink Sleeve is a versatile and effective solution for safeguarding cables, hoses, and wires in demanding industrial environments. The installation process of this innovative sleeve is straightforward and can be accomplished efficiently with the help of a heat gun. In this step-by-step guide, we will explore the process of installing Fabric Heat Shrink Sleeve to ensure comprehensive and reliable cable protection.

Step 1: Prepare the Work Area

Before beginning the installation, it's essential to prepare the work area. Ensure that the cables, hoses, or wires to be protected are clean and free from any debris or contaminants. If needed, use a clean cloth or compressed air to remove any dirt or moisture.

Step 2: Choose the Right Sleeve Size

Select the appropriate size of Fabric Heat Shrink Sleeve for the cables, hoses, or wires you want to protect. Measure the outer diameter of the components accurately to choose the correct sleeve size. It is crucial to have a snug fit for optimal protection.

Step 3: Slide the Sleeve Over the Components

Carefully slide the Fabric Heat Shrink Sleeve over the cables, hoses, or wires. Ensure that the sleeve covers the entire length of the components that require protection. For irregularly shaped hoses or cables, the sleeve's flexibility allows it to conform precisely to the contours, providing a custom fit.

Step 4: Apply Heat

Using a heat gun, apply heat evenly to the Fabric Heat Shrink Sleeve. The heat activates the shrinking process, causing the sleeve to contract and conform tightly to the shape of the cables, hoses, or wires. Keep the heat gun at a safe distance to avoid overheating or damaging the sleeve.

Step 5: Check for Complete Shrinkage

Monitor the shrinking process to ensure that the Fabric Heat Shrink Sleeve has fully contracted around the components. Verify that there are no gaps or loose sections on the sleeve's surface, as a complete seal is essential for comprehensive protection.

Step 6: Allow Cooling and Settling

After the sleeve has completely shrunk and molded around the cables, hoses, or wires, allow it to cool down and settle. This cooling period ensures a secure and stable fit, enhancing the overall effectiveness of the protective layer.

Step 7: Conduct Quality Check

Perform a thorough quality check to ensure the Fabric Heat Shrink Sleeve has been installed correctly and securely. Verify that the sleeve is in perfect contact with the cables, hoses, or wires and that there are no exposed areas.

Step 8: Test the Protected Components

Finally, conduct a functional test to ensure that the protected cables, hoses, or wires are operating correctly. Verify that there are no disruptions or abnormalities in electrical or fluid transfer systems.

Conclusion

Installing Fabric Heat Shrink Sleeve is a straightforward and efficient process that provides comprehensive protection to cables, hoses, and wires in demanding industrial environments. By following this step-by-step guide, you can ensure the proper installation of the sleeve, enhancing the safety, reliability, and longevity of critical electrical and fluid transfer systems. The versatility and ease of installation make Fabric Heat Shrink Sleeve an invaluable solution for cable protection across diverse industries.