#Product Trends

How Burst Protection Sleeves for Hydraulic Hoses Work

Burst Protection Sleeves for Hydraulic Hoses

Burst protection sleeves for hydraulic hoses are crucial components that ensure the safety and reliability of hydraulic systems. Understanding how these sleeves work is essential for anyone involved in the operation and maintenance of hydraulic machinery. In this article, we will delve into the mechanics of burst protection sleeves and their role in preventing hydraulic hose failures.

The Mechanics of Hydraulic Hose Failures

Hydraulic hoses are subjected to high pressures and mechanical stresses during operation. Over time, these hoses can develop weaknesses, such as abrasions, cuts, or fatigue cracks. When these weaknesses reach a critical point, a hose can fail catastrophically, releasing high-pressure hydraulic fluid.

The Role of Burst Protection Sleeves

Burst protection sleeves are engineered to contain the force and fluid release in the event of a hydraulic hose failure. Here's how they work:

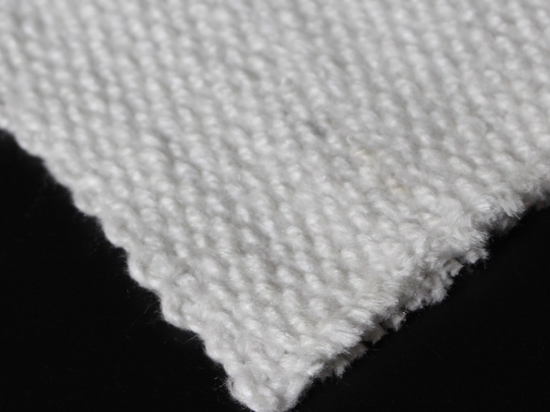

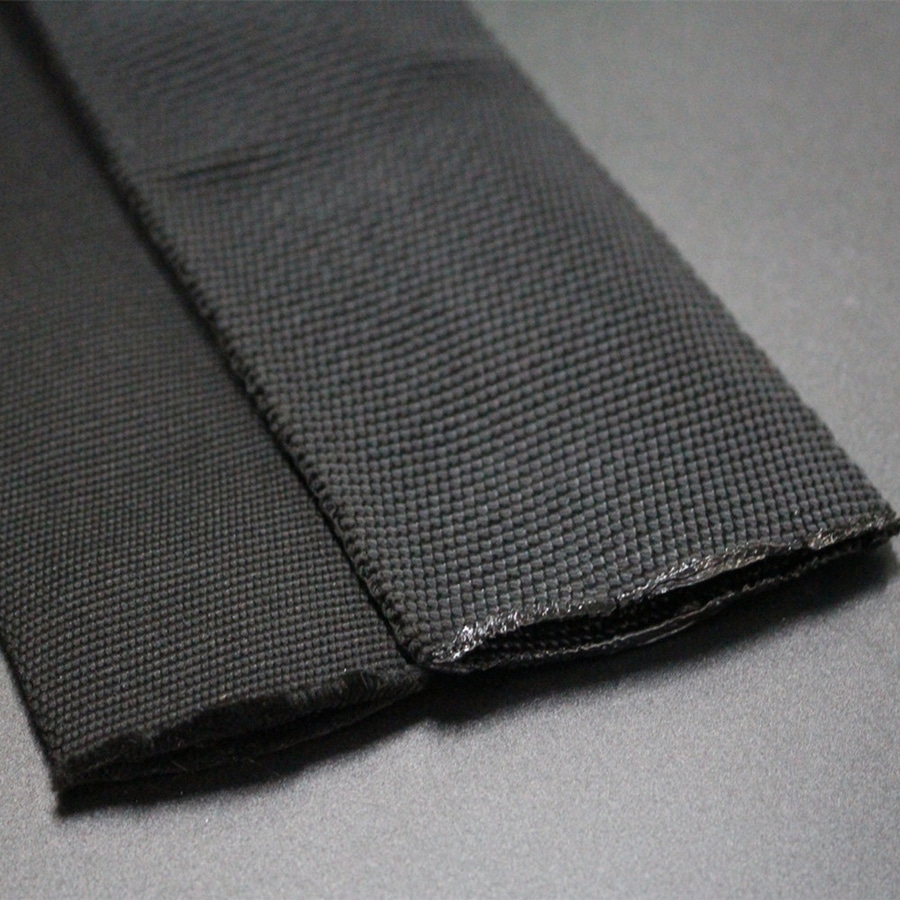

Materials: Burst protection sleeves are typically made from durable, high-strength materials such as woven fiberglass, Kevlar, or silicone-coated fabric. These materials are chosen for their resistance to heat, abrasion, and chemicals.

Construction: The sleeve is designed to slide over the hydraulic hose, forming a protective layer. It is typically flexible and can be customized to fit various hose sizes.

Containment: When a hose bursts, the burst protection sleeve tightly constricts around the hose, creating a barrier that limits the rapid release of hydraulic fluid. This containment prevents fluid from spraying uncontrollably.

Cooling Effect: Burst protection sleeves can also provide a cooling effect by dissipating heat generated by the escaping hydraulic fluid. This can reduce the risk of fire in high-temperature environments.

Enhancing Safety and Reliability

The primary purpose of burst protection sleeves is to enhance safety and reliability in hydraulic systems. By effectively containing hydraulic fluid in the event of a hose failure, these sleeves:

Minimize Personnel Injury Risk: By preventing fluid from spraying at high pressure, burst protection sleeves reduce the risk of severe injuries to operators and bystanders.

Limit Environmental Impact: The containment of hydraulic fluid helps prevent environmental contamination, minimizing harm to the surroundings.

Reduce Downtime and Repair Costs: Hydraulic hose failures can be costly in terms of operational downtime and equipment damage. Burst protection sleeves mitigate these risks.