#Product Trends

Hydraulic Hose Protection: Ensuring Durability and Safety

Hydraulic Hose Protection

In the world of industrial machinery and heavy equipment, hydraulic hoses are vital conduits for transmitting fluids and powering various components. These hoses are subjected to harsh conditions, including abrasion, high pressures, and extreme temperatures, which can lead to wear and potential damage. To safeguard these critical components, hydraulic hose protection is essential.

The Importance of Hydraulic Hose Protection:

Preventing Abrasion: Hydraulic hoses often run in close proximity to moving parts or rough surfaces. Without adequate protection, they can suffer from abrasion, leading to leaks and reduced performance. Protective sleeves act as a barrier, shielding hoses from abrasion damage.

Enhancing Safety: Hydraulic systems operate under high pressure, and a hose failure can result in serious injury or equipment damage. Protection sleeves add an extra layer of safety by containing leaks and preventing catastrophic failures.

Extending Hose Lifespan: By preventing wear and tear, hydraulic hose protection sleeves prolong the life of hoses, reducing the frequency of replacements and maintenance costs.

Temperature Control: Hydraulic systems can generate significant heat. Protection sleeves with high-temperature resistance help maintain the ideal operating temperature of the hoses, ensuring consistent performance.

Types of Hydraulic Hose Protection:

Nylon Sleeves: Nylon protective sleeves provide excellent abrasion resistance and are ideal for protecting hoses in rugged environments.

Polyester Sleeves: Polyester sleeves offer durability and resistance to wear and tear, making them suitable for various industrial applications.

Polypropylene Sleeves: Polypropylene sleeves provide chemical resistance and are often used in applications where hoses come into contact with corrosive substances.

Nylon+Aramid Sleeves: Combining nylon and aramid fibers, these sleeves offer enhanced protection against abrasion, chemicals, and heat.

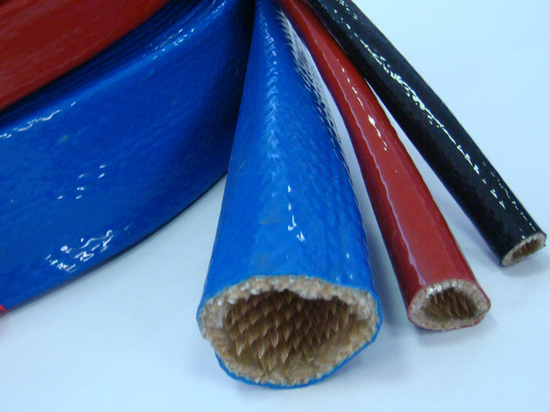

Silicone Fire Sleeves: Designed for extreme heat environments, silicone fire sleeves offer outstanding resistance to high temperatures, making them essential for critical applications.

Fiberglass Sleeves: Fiberglass sleeves provide excellent heat resistance and are commonly used to protect hoses in high-temperature settings.

Nylon 66 Expandable Braided Sleeves: These sleeves offer flexibility and expandability, making them suitable for applications with varying hose sizes.

Silicone-Coated Fiberglass Sleeves: Combining the heat resistance of fiberglass with silicone coating, these sleeves are effective in protecting hoses from both heat and abrasion.