#Product Trends

Why use the exhaust heat blanket?

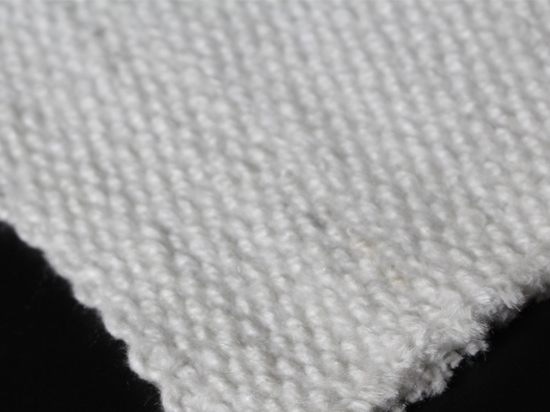

Exhaust heat blankets

Exhaust heat blankets are used for several important reasons in various applications, primarily in automotive and industrial contexts, to manage and control the heat generated by exhaust systems. Here are the key reasons why exhaust heat blankets are employed:

Heat Management: One of the primary purposes of exhaust heat blankets is to manage and control the heat produced by exhaust systems. By wrapping or installing these blankets around hot components, they help insulate and contain the heat, preventing it from spreading to surrounding areas. This can be crucial for maintaining a safe and efficient operating environment.

Temperature Control: Heat blankets can help maintain the optimal operating temperature within the exhaust system. This can be important for emissions control systems in vehicles and industrial equipment, as they often rely on precise temperature ranges for efficient operation.

Protection of Surrounding Components: Exhaust systems can generate extremely high temperatures, which can be damaging to nearby components, particularly those made of plastic, rubber, or other heat-sensitive materials. Exhaust heat blankets act as a barrier, protecting these components from excessive heat, which can lead to melting, deformation, or failure.

Safety: Protecting personnel and operators from accidental burns or injuries is a significant concern, especially in applications where exhaust systems are in close proximity to working areas. Heat blankets reduce the external temperature of the exhaust system, minimizing the risk of burns and heat-related accidents.

Fire Prevention: In some cases, exhaust heat blankets are used to prevent the risk of fires. By containing and insulating the heat generated by the exhaust system, they reduce the likelihood of nearby flammable materials catching fire due to prolonged exposure to high temperatures.

Improved Performance: Managing and controlling heat with exhaust heat blankets can lead to improved performance in various ways. For example, in automotive applications, reducing underhood temperatures can enhance engine performance and efficiency. In industrial settings, optimizing the temperature of exhaust gases can improve overall system efficiency.

Emissions Control: In vehicles and industrial equipment, maintaining the right temperature in the exhaust system is critical for emissions control. Some emissions control systems, like catalytic converters, require specific operating temperatures to function effectively. Heat blankets can help maintain these temperatures, leading to cleaner emissions.

Energy Efficiency: By containing and reusing heat from exhaust gases, heat blankets can contribute to improved energy efficiency in some industrial processes. They may help preheat air or water for other industrial applications, reducing energy consumption.