#Product Trends

Silicone fiberglass sleeving application in Automotive

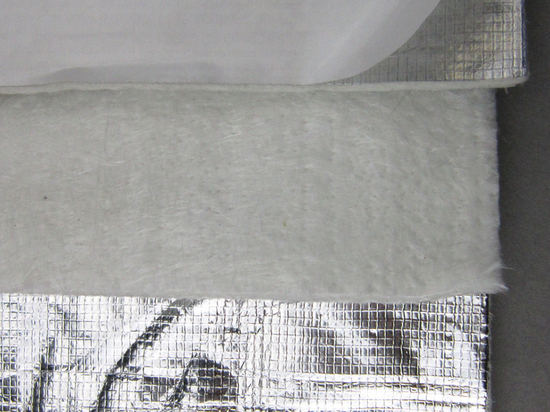

Silicone fiberglass sleeving

Silicone fiberglass sleeving finds versatile applications in automotive components, offering a reliable solution for thermal and electrical insulation. Used extensively in vehicle accessories, it provides the following benefits:

Exhaust System Protection: Silicone fiberglass sleeving is employed to insulate and protect wires and cables in the exhaust system. It can withstand high temperatures, preventing heat damage to nearby components.

Engine Compartment Wiring: In the engine compartment, where temperatures can be elevated, the sleeving serves as a protective layer for wiring and cables. It ensures electrical components remain insulated and functional under challenging conditions.

Heat Shielding: The material's heat-resistant properties make it suitable for heat shielding applications. It can be wrapped around sensitive components to shield them from the intense heat generated by the engine or exhaust system.

Electrical Insulation: Silicone fiberglass sleeving acts as an effective electrical insulator, preventing short circuits and electrical malfunctions. It is commonly used in wiring harnesses and other electrical systems within vehicles.

Thermal Management: In areas where temperature control is crucial, such as around the transmission or braking systems, the sleeving helps manage heat, contributing to overall vehicle performance and safety.

Abrasion Resistance: The addition of fiberglass enhances the sleeving's mechanical strength, providing resistance against abrasion and physical wear. This is particularly beneficial in automotive applications where friction and movement are common.

Chemical Resistance: The silicone material used in the sleeving exhibits resistance to various chemicals, making it suitable for use in environments where exposure to automotive fluids is a consideration.