#Product Trends

What is the Braided Biaxial Fiberglass Sleeving?

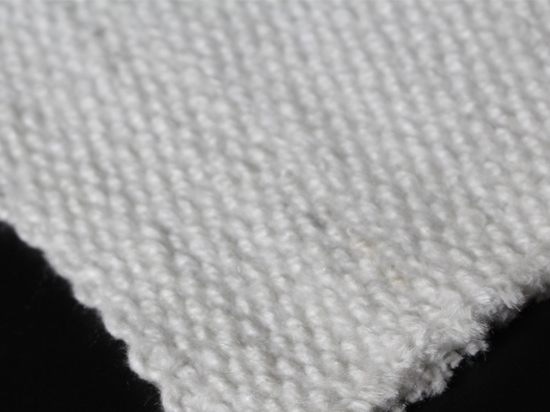

Braided Biaxial Fiberglass Sleeving

Braided biaxial fiberglass sleeving is a type of protective covering used in various industries to protect wires, cables, and other components. It is made from interwoven fiberglass fibers that are braided in a biaxial pattern, providing several key benefits:

Durability: Fiberglass is known for its strength and resistance to wear and tear. The braided structure enhances its durability, making it suitable for harsh environments.

Heat Resistance: Fiberglass sleeving can withstand high temperatures, often up to several hundred degrees Celsius, depending on the specific product. This makes it ideal for applications where heat resistance is crucial.

Electrical Insulation: Fiberglass is a good electrical insulator, providing protection against electrical interference and ensuring the safe operation of electrical components.

Flexibility: The biaxial braid allows the sleeving to be flexible, making it easy to install over irregular shapes and providing a snug fit around components.

Chemical Resistance: Fiberglass is resistant to many chemicals, oils, and solvents, making it suitable for use in chemical plants, refineries, and other industrial settings.

Lightweight: Despite its strength and durability, fiberglass is relatively lightweight, adding minimal weight to the components it protects.

Applications

Aerospace: Used to protect wiring and cabling in aircraft and spacecraft due to its high strength-to-weight ratio and thermal resistance.

Automotive: Used in engine compartments and other high-temperature areas to protect wires and hoses.

Marine: Provides protection against saltwater and other harsh marine environments.

Industrial: Used in factories and plants to protect cables and hoses from abrasion, heat, and chemicals.

Electronics: Provides insulation and protection for wiring in electronic devices and assemblies.

Installation Tips

Measure and Cut: Measure the length of sleeving required and cut it with scissors or a hot knife to prevent fraying.

Expand and Insert: The sleeving can be expanded to fit over connectors and irregular shapes. Insert the component into the sleeving and then release to allow it to contract for a snug fit.

Secure Ends: Use heat-shrink tubing, tape, or clamps to secure the ends of the sleeving and prevent fraying.