#Product Trends

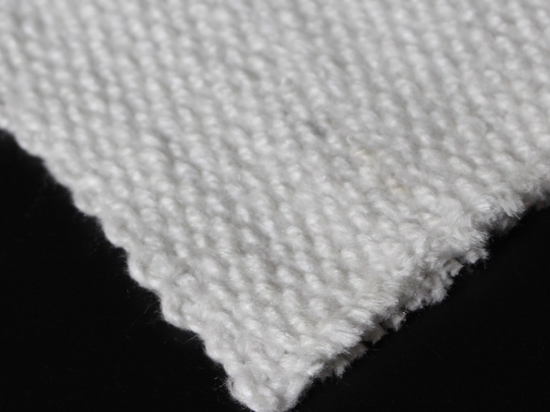

silica needle mat

silica fiberglass needle mat

Silica needle mat is a high-performance insulating material composed primarily of amorphous silica fibers. These fibers are intricately woven to form a mat that provides exceptional thermal insulation and resistance to high temperatures, making it ideal for various industrial applications. The unique needle-punching technique used in its fabrication ensures a robust structure that can withstand harsh environments.

One of the key features of silica needle mat is its low thermal conductivity, which significantly reduces heat transfer and helps in maintaining optimal temperatures in industrial processes. This characteristic is particularly valuable in industries such as petrochemicals, aerospace, and automotive, where thermal management is crucial. Additionally, the mat's resistance to thermal shock and chemical inertness ensures long-term stability and reliability even in extreme conditions.

Silica needle mat is also lightweight and flexible, allowing for easy installation and manipulation to fit complex shapes and surfaces. Its durability and mechanical strength make it suitable for use as insulation in furnaces, kilns, and other high-temperature equipment. Furthermore, its non-combustible nature enhances safety in environments where fire hazards are a concern.

Environmental and health considerations are also addressed by the silica needle mat, as it is free from asbestos and other harmful fibers, ensuring a safer alternative for workers and end-users. The material's recyclability and long service life contribute to sustainable practices in industrial settings.

In summary, silica needle mat combines high thermal performance, mechanical resilience, and safety, making it an indispensable material for a wide range of high-temperature applications. Its innovative design and versatile properties offer significant advantages in efficiency, safety, and environmental impact, positioning it as a superior choice in modern industrial insulation solutions.