#Industry News

How does a heat reflective sleeve improve engine performance?

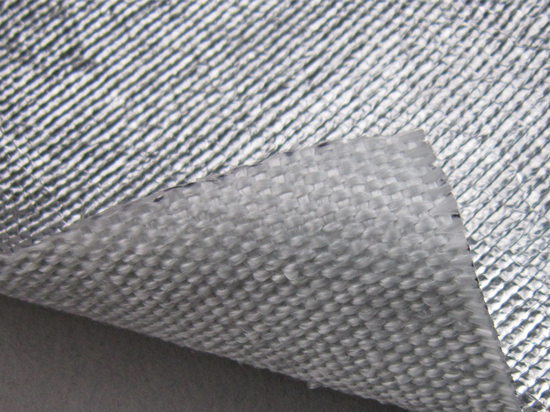

heat reflective sleeve

A heat reflective sleeve can improve engine performance in several ways:

Heat Management: By wrapping components like hoses, wires, or pipes with a heat reflective sleeve, heat transfer to adjacent components or systems can be reduced. This helps in maintaining optimal operating temperatures, preventing overheating, and improving overall efficiency.

Reduced Heat Soak: Heat reflective sleeves can prevent heat soak, where components absorb heat from their surroundings even after the source of heat is removed. This is particularly beneficial for components located near exhaust systems or other heat-emitting parts of the engine.

Enhanced Air Intake Temperature: By insulating components that affect air intake, such as intake pipes or the air filter housing, a heat reflective sleeve can help maintain lower air intake temperatures. Cooler air intake can lead to denser air entering the engine, potentially improving combustion efficiency and increasing horsepower.

Protection from Radiant Heat: Radiant heat from nearby sources, like exhaust manifolds or turbochargers, can be effectively blocked by heat reflective sleeves. This protection not only improves the longevity of surrounding components but also ensures consistent performance under high-temperature conditions.

Fuel Efficiency: By maintaining optimal operating temperatures and reducing the workload on cooling systems, heat reflective sleeves can contribute to improved fuel efficiency. This is particularly noticeable in high-performance or turbocharged engines where heat management plays a crucial role in performance.

Overall, the primary benefits of a heat reflective sleeve lie in maintaining consistent temperatures, enhancing component durability, and optimizing engine performance by mitigating the negative effects of heat.