#Industry News

What are the benefits of using a heat reflective sleeve in automotive applications?

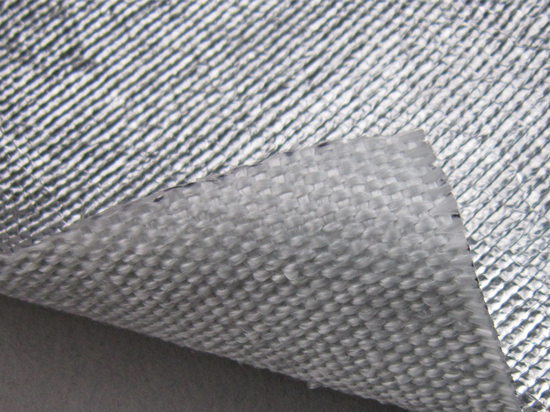

heat reflective sleeve

Heat reflective sleeves offer several benefits in automotive applications:

Heat Protection: They help in shielding sensitive components from high temperatures, such as wires, hoses, and cables, thereby preventing overheating and potential damage.

Improved Performance: By reducing radiant heat transfer, these sleeves can enhance the performance and reliability of components like fuel lines, brake lines, and electrical wiring.

Energy Efficiency: They contribute to energy efficiency by minimizing heat loss or gain in critical areas, which can improve overall vehicle efficiency and reduce fuel consumption.

Extended Lifespan: Components wrapped in heat reflective sleeves tend to have a longer lifespan due to reduced exposure to heat-related degradation, such as premature aging of rubber hoses or electrical insulation.

Safety Enhancement: By lowering the surface temperature of components, these sleeves can reduce the risk of accidental burns or fires, making automotive systems safer for maintenance and operation.

Corrosion Prevention: Some sleeves offer protection against corrosion by keeping moisture away from critical components, particularly in high-temperature environments.

Versatility: They are available in various materials and configurations to suit different application needs, from lightweight reflective films to more robust ceramic fiber-based sleeves.

Overall, heat reflective sleeves play a crucial role in maintaining the efficiency, reliability, and safety of automotive systems subjected to high temperatures.