#Industry News

What are the key advantages of using silicone coated fiberglass sleeve in industrial applications?

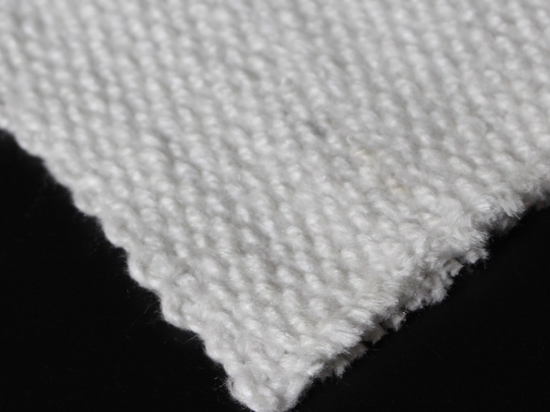

silicone coated fiberglass sleeve

Silicone coated fiberglass sleeves offer several key advantages in industrial applications:

Heat Resistance: They can withstand high temperatures, typically up to 500°F (260°C) or more, making them suitable for protecting hoses, cables, and wires in environments with extreme heat.

Fire Resistance: The silicone coating provides a layer of fire resistance, making these sleeves ideal for applications where fire safety is crucial.

Abrasion Resistance: The fiberglass base material combined with silicone coating enhances durability and resistance to abrasion, ensuring longer lifespan in harsh industrial environments.

Chemical Resistance: They are resistant to many chemicals and oils, which adds to their versatility in various industrial settings.

Flexibility: Despite their toughness, silicone coated fiberglass sleeves remain flexible, allowing for easy installation over irregular shapes and contours.

Electrical Insulation: They provide electrical insulation properties, which can be beneficial for protecting wires and cables in electrical and electronic applications.

Water and Weather Resistance: Silicone coatings offer protection against water ingress and weathering, enhancing the sleeves' performance in outdoor or wet conditions.

UV Resistance: They are resistant to ultraviolet (UV) radiation, ensuring they maintain their integrity and performance over time when exposed to sunlight.

Overall, silicone coated fiberglass sleeves are valued in industries such as automotive, aerospace, marine, and manufacturing for their combination of heat resistance, durability, and protective qualities.