#Product Trends

Why use the aluminized fiberglass sleeving to protect the automotive rubber hose?

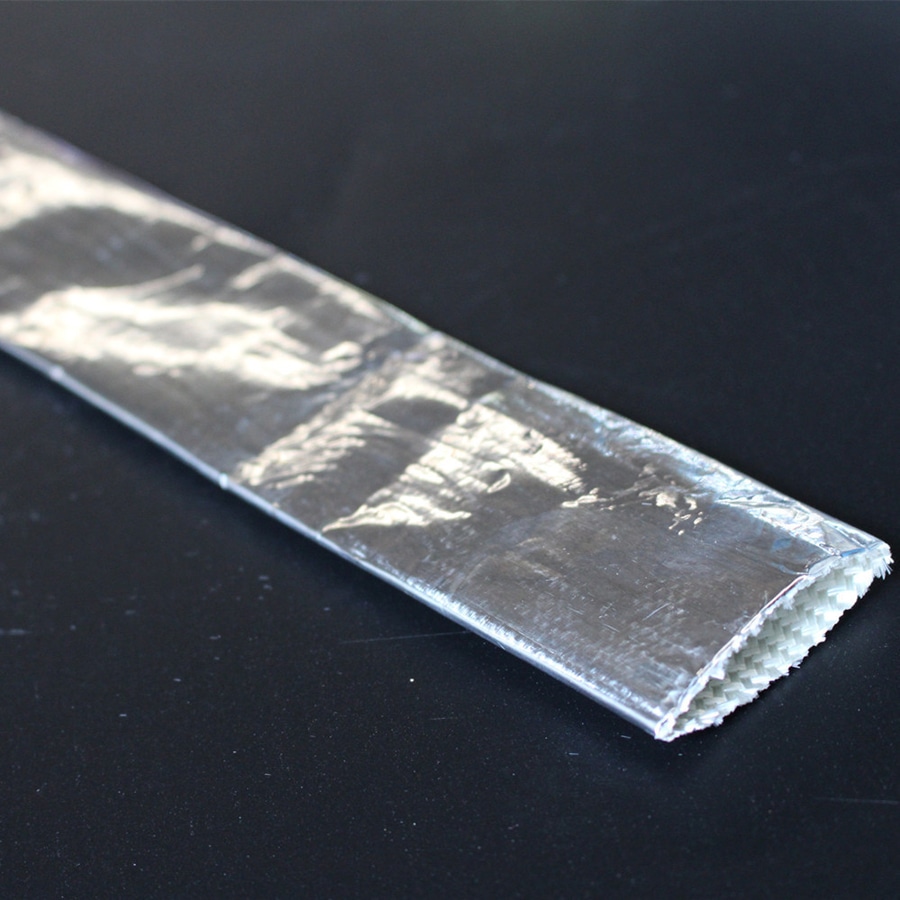

aluminized fiberglass sleeving

A high-performance sports car has several critical components operating at high temperatures, including the exhaust system and turbocharger. The rubber hoses in this vehicle are responsible for transporting fluids and air under significant pressure and heat. The proximity of these hoses to hot components like the exhaust manifold and turbocharger poses a risk of heat damage.

Application of Aluminized Fiberglass Sleeving:

Heat Protection:

Problem: The rubber hoses are subjected to extreme temperatures, sometimes exceeding 150°C (302°F) due to close proximity to the exhaust system.

Solution: Aluminized fiberglass sleeving is applied around the hoses. The aluminized coating reflects a substantial amount of radiant heat away from the hoses, reducing the temperature they are exposed to. This helps prevent the rubber from softening, cracking, or deteriorating due to excessive heat.

Improved Longevity:

Problem: Continuous exposure to high temperatures can cause the rubber hoses to degrade over time, leading to potential leaks or failures.

Solution: The insulation properties of the fiberglass sleeving help maintain a lower temperature around the hose, extending its lifespan. The sleeving acts as a thermal barrier, mitigating the effects of heat and thereby prolonging the hose's functional life.

Abrasion Resistance:

Problem: The rubber hoses are subjected to vibration and movement, which can cause them to rub against other engine components or parts.

Solution: The fiberglass sleeving provides an additional layer of protection against abrasion. It shields the rubber hose from wear and tear caused by physical contact and vibration, reducing the risk of hose damage.

Safety and Reliability:

Problem: A failure in the hose could lead to engine damage, reduced performance, or even safety hazards.

Solution: By protecting the hoses with aluminized fiberglass sleeving, the risk of heat-induced failures and damage is minimized. This contributes to overall vehicle safety and reliability, ensuring that the hoses perform effectively under demanding conditions.

In this high-performance sports car, the use of aluminized fiberglass sleeving around the rubber hoses provides essential protection against heat, abrasion, and chemical damage. This practical application illustrates how this type of sleeving enhances the durability and performance of automotive components in extreme conditions.