#Product Trends

Silica cloth welding blanket

What is the purpose of a silica cloth welding blanket?

Understanding Silica Cloth Welding Blankets: Purpose, Performance, and Practical Applications

What is a Silica Cloth Welding Blanket?

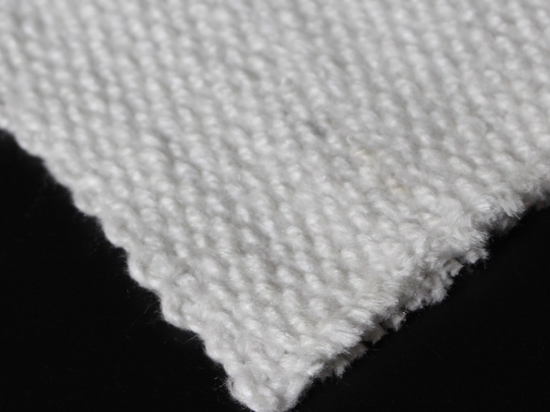

A silica cloth welding blanket is a high-performance protective cover made from woven silica fabric. Silica cloth, known for its excellent thermal resistance, is an ideal material for shielding surfaces and workers from the intense heat and sparks generated during welding and other high-temperature processes.

Performance Characteristics

Exceptional Heat Resistance: Silica cloth can withstand temperatures up to 1,800°F (980°C), making it highly effective in environments with extreme heat. This makes it an indispensable tool for protecting both equipment and personnel.

Flame Retardant: The silica fabric is inherently flame-resistant, preventing fire hazards and ensuring safety in welding operations.

Durability: Silica cloth is highly durable, withstanding abrasive conditions and offering long-term use even in the most demanding environments.

Low Thermal Conductivity: This property ensures minimal heat transfer, effectively protecting underlying surfaces and reducing heat damage.

Chemical Resistance: Silica fabric resists various chemicals and molten metal splashes, contributing to its versatility in different industrial applications.

Practical Applications

Welding Operations:

Protective Cover: Silica cloth welding blankets are commonly used to cover surfaces, such as floors and workbenches, to protect them from welding sparks and spatter. For instance, in automotive repair shops, these blankets prevent damage to vehicle parts and workshop floors.

Worker Protection: Welders use these blankets to shield themselves and their surroundings from excessive heat and potential fire hazards. In a construction setting, using silica blankets can minimize heat-related risks and enhance safety.

Metalworking and Fabrication:

Heat Shielding: During processes like cutting and grinding, silica blankets can be employed to shield sensitive components and surroundings from intense heat. In steel fabrication, they protect critical components from thermal damage and maintain the integrity of finished products.

Industrial Maintenance:

Protecting Equipment: In facilities where high-temperature operations are frequent, such as foundries or glass manufacturing plants, silica cloth blankets are used to safeguard equipment from heat exposure and accidental splashes of molten materials.

Emergency Response:

Fire Prevention: Silica cloth blankets are also valuable in emergency situations, such as during the containment of fire hazards or in industries where rapid heat management is required to prevent accidents.

User Testimonials

John D., Industrial Welder: "In our welding shop, the silica cloth blankets are a game changer. They hold up incredibly well under high temperatures and have significantly reduced the number of fire incidents. The durability and heat resistance are second to none."

Sarah L., Metal Fabricator: "We use silica blankets to protect our machinery from intense heat during metal fabrication. The blankets' resistance to molten metal and sparks has saved us a lot of maintenance work and potential damage costs."

Michael R., Construction Site Supervisor: "For on-site welding jobs, these blankets provide essential protection for surfaces and workers. The safety benefits are evident, and they help us comply with safety regulations more effectively."