#Product Trends

Silicone-Impregnated Fiberglass Fabric: Exceptional Flexibility and Protection for Heat-Resistant Applications

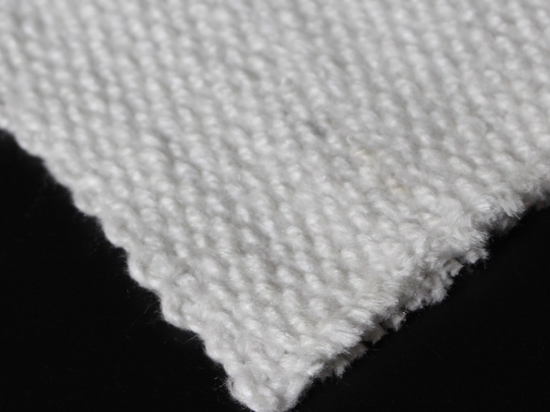

Silicone-impregnated fiberglass fabric

In industries where heat resistance and durability are paramount, silicone-impregnated fiberglass fabric emerges as a leading choice for protective applications. This innovative material is engineered to provide exceptional flexibility while offering outstanding insulation properties, making it ideal for use in insulating blankets, heat shields, and a variety of heat-resistant components.

The foundation of silicone-impregnated fiberglass fabric lies in its high-quality fiberglass base, which boasts a remarkable temperature rating of up to 1000°F (550°C). This inherent capability allows the fabric to withstand extreme heat conditions, ensuring that it remains functional and reliable in demanding environments. However, what truly sets this fabric apart is its silicone coating, which is rated for continuous exposure to temperatures up to 550°F (287°C). This combination of materials creates a protective barrier that not only insulates but also enhances the overall performance of the fabric.

One of the standout features of silicone-impregnated fiberglass fabric is its water and oil resistance. The silicone coating effectively repels moisture and oils, preventing the fabric from absorbing harmful substances that could compromise its integrity. This property is particularly beneficial in applications where exposure to liquids is a concern, such as in industrial settings or automotive environments. By providing an additional layer of protection against environmental factors, this fabric enhances the longevity and reliability of the products made from it.

Safety is another critical consideration in high-heat applications, and silicone-impregnated fiberglass fabric excels in this regard. The silicone coating is inherently flame retardant, significantly reducing the risk of ignition and ensuring compliance with safety standards. Furthermore, this fabric produces low smoke when exposed to flames, minimizing the potential hazards associated with smoke inhalation in the event of a fire.

Flexibility is a crucial attribute for many applications, and silicone-impregnated fiberglass fabric delivers exceptional performance in this area. The fabric maintains its pliability even under extreme conditions, allowing it to be easily manipulated and shaped for various uses. Its dry surface does not stick to sewing tables, making it easier to sew, drape, and handle during fabrication. This ease of use not only streamlines the manufacturing process but also allows for intricate designs and tailored applications.

Additionally, silicone-impregnated fiberglass fabric offers excellent puncture and tear resistance. Its robust construction can withstand the rigors of industrial use, ensuring that it remains intact and effective even in challenging environments. This durability reduces the need for frequent replacements, ultimately saving time and costs for businesses.

In summary, silicone-impregnated fiberglass fabric is an exceptional material that combines flexibility, heat resistance, and durability, making it ideal for a wide range of applications. Its unique properties, including water and oil resistance, flame retardance, and low smoke production, make it a reliable choice for industries such as automotive, aerospace, manufacturing, and more. By selecting silicone-impregnated fiberglass fabric, you invest in a superior protection fabric that enhances the performance and safety of your heat-resistant products.