#Product Trends

How Does Basalt Fiber Fabric Enhance Durability and Sustainability in Modern Manufacturing?

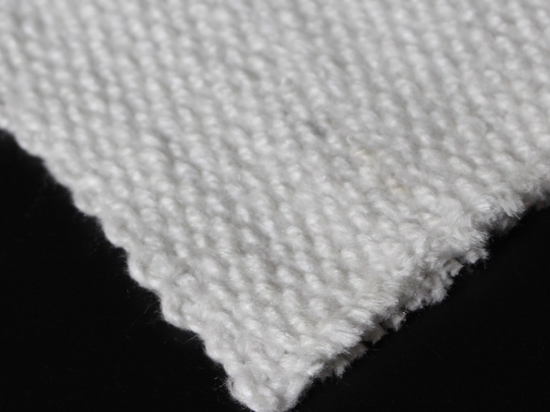

Basalt Fiber Fabric

In today’s manufacturing landscape, businesses are constantly seeking materials that not only meet high-performance standards but also contribute to sustainability goals. Basalt fiber fabric stands out as an innovative solution that addresses both durability and environmental responsibility. Let’s explore how this remarkable material enhances durability and sustainability in modern manufacturing processes.

1. Exceptional Strength and Longevity

Basalt fiber fabric is known for its impressive mechanical strength, which allows it to withstand demanding conditions without compromising its integrity. This durability translates into longer product lifespans, reducing the frequency of replacements and minimizing waste. In applications ranging from automotive components to construction materials, using basalt fiber fabric can significantly extend the service life of products, leading to lower costs and reduced resource consumption.

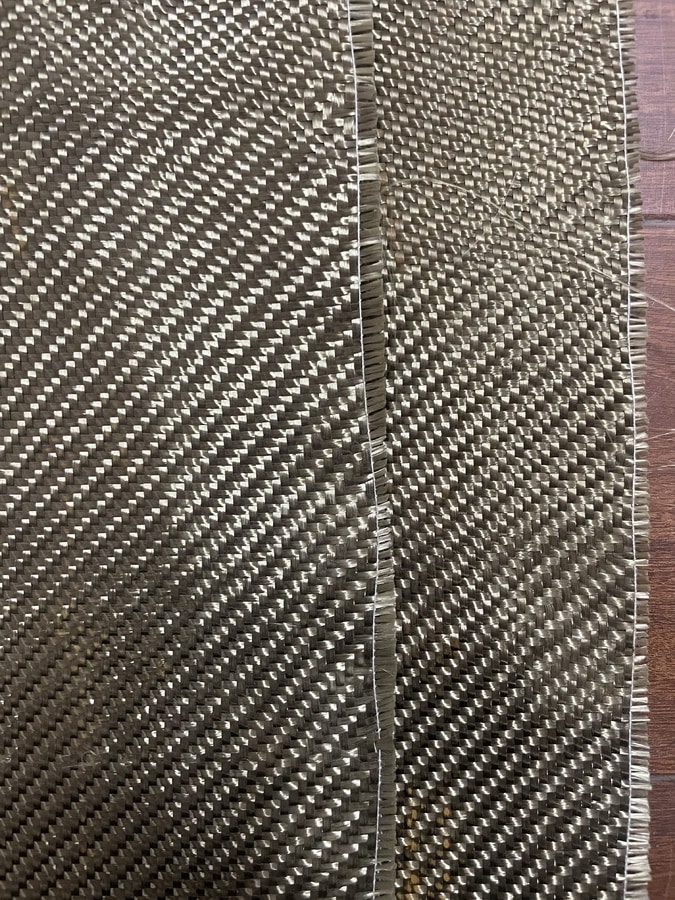

2. High Thermal Resistance

One of the key benefits of basalt fiber fabric is its ability to endure extreme temperatures, withstanding up to 1,000°C (1,832°F). This exceptional thermal resistance makes it ideal for applications in industries such as aerospace and manufacturing, where components are frequently exposed to high heat. By providing reliable insulation and protection, basalt fiber fabric helps maintain performance and safety in critical applications, enhancing overall durability.

3. Resistance to Environmental Factors

Basalt fiber fabric exhibits outstanding resistance to environmental degradation, including moisture, chemicals, and UV radiation. Unlike traditional materials that may absorb moisture or degrade under exposure to harsh chemicals, basalt fiber remains unaffected, making it suitable for use in challenging environments. This resistance ensures that products maintain their performance characteristics over time, contributing to durability and reducing the need for repairs or replacements.

4. Eco-Friendly Production

Basalt fiber is derived from natural volcanic rock, making it a sustainable alternative to synthetic fibers. The manufacturing process for basalt fiber fabric is energy-efficient, requiring less energy compared to the production of fiberglass or carbon fiber. Additionally, basalt fiber is 100% recyclable, further reducing its environmental impact. As industries strive to implement eco-friendly practices, basalt fiber fabric aligns perfectly with these sustainability goals.

5. Contribution to Lightweight Design

The lightweight nature of basalt fiber fabric allows manufacturers to reduce the overall weight of their products without sacrificing strength or durability. This characteristic is particularly valuable in the automotive and aerospace sectors, where every gram counts. Lighter components not only enhance fuel efficiency but also lower emissions, contributing to more sustainable manufacturing practices.

6. Versatile Applications for Diverse Industries

Basalt fiber fabric is incredibly versatile, with applications spanning a wide range of industries, including automotive, construction, aerospace, and energy. Its adaptability allows manufacturers to integrate it into various products, from heat shields and insulation materials to composite reinforcements. This versatility ensures that businesses can leverage basalt fiber fabric to meet specific performance and sustainability requirements across different sectors.