#Product Trends

What Makes Fiberglass Woven Tape the Ideal Solution for Heat and Abrasion Resistance?

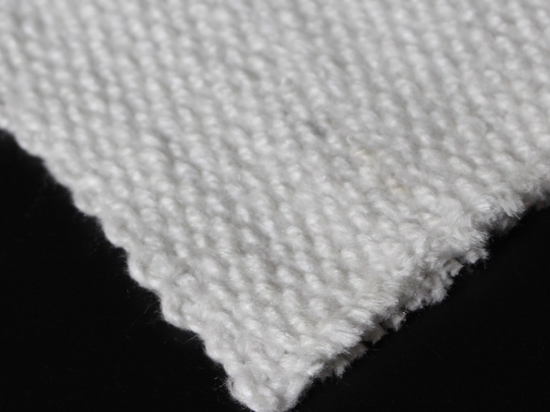

Fiberglass Woven Tape

In industrial environments, the demand for materials that can withstand extreme conditions is paramount. Among these, fiberglass woven tape stands out as a preferred choice for heat and abrasion resistance. This versatile product is utilized across various industries for its unique properties that ensure the protection and longevity of critical components. Here, we delve into the key features that make fiberglass woven tape an ideal solution for heat and abrasion resistance.

1. Superior Heat Resistance

Fiberglass woven tape is engineered to endure high temperatures, typically up to 1,000°F (538°C). This makes it an excellent choice for applications involving heat exposure, such as in automotive exhaust systems, industrial machinery, and HVAC insulation. Its ability to maintain structural integrity and effectiveness in extreme temperatures ensures that it provides reliable protection against heat damage, thereby enhancing the longevity of the components it covers.

2. High Abrasion Resistance

The woven structure of fiberglass tape enhances its resistance to wear and tear. It is designed to withstand the abrasive forces encountered in demanding environments, such as those found in manufacturing and heavy machinery. This durability prevents fraying and damage, ensuring that the tape remains intact and effective over time. By using fiberglass woven tape, businesses can significantly reduce maintenance needs and the frequency of replacements.

3. Lightweight Yet Strong

Fiberglass woven tape combines strength with lightweight properties, making it easy to handle and apply. Its flexibility allows it to conform to various shapes and surfaces without compromising its protective qualities. This characteristic is particularly beneficial in applications where space is limited or where complex geometries need to be covered. The ease of installation helps streamline operations, reducing downtime and labor costs.

4. Chemical and Moisture Resistance

In addition to its heat and abrasion resistance, fiberglass woven tape offers excellent resistance to a wide range of chemicals and moisture. This makes it suitable for use in environments where exposure to oils, solvents, and other corrosive substances is common. By providing a protective barrier, fiberglass woven tape helps prevent deterioration and damage to critical components, further enhancing its effectiveness in various industrial applications.

5. Versatile Applications

The adaptability of fiberglass woven tape allows it to be used in diverse applications. Whether for insulating pipes, reinforcing hoses, or protecting cables, this tape meets the unique needs of various industries, including automotive, aerospace, and construction. Its versatility means that companies can rely on a single product to address multiple challenges, streamlining their procurement and inventory processes.

6. Cost-Effective Solution

Investing in fiberglass woven tape is a strategic move for businesses looking to enhance operational efficiency. By reducing the risk of equipment failure and minimizing maintenance costs, this tape offers a cost-effective solution for protecting valuable assets. Its long-lasting properties translate to fewer replacements and repairs, allowing companies to allocate resources more effectively.