#Product Trends

What Makes Ceramic Fiber Fabric the Best Solution for Fire and Heat Protection?

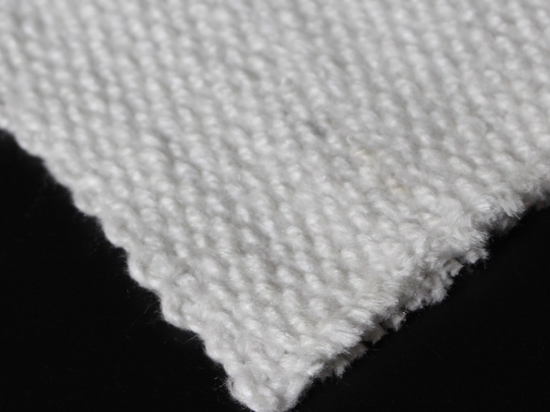

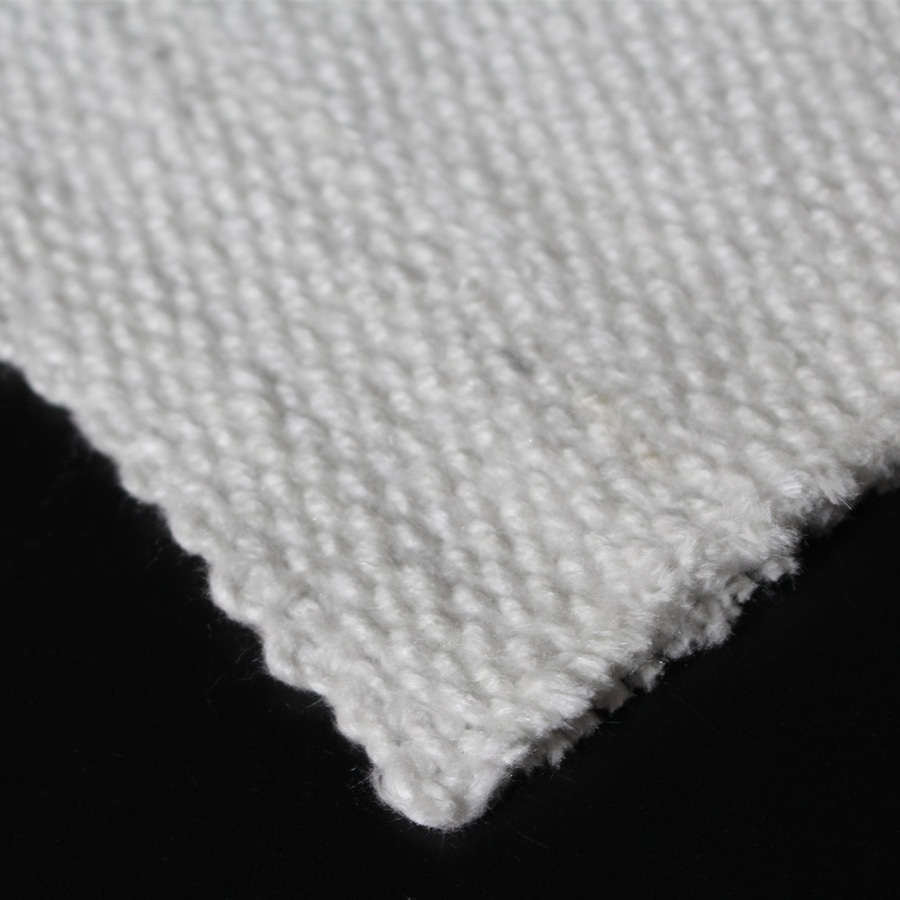

Ceramic Fiber Fabric

In industries where high temperatures and fire hazards are prevalent, effective heat protection is essential. Ceramic fiber fabric has emerged as one of the leading solutions for fire and heat protection due to its unique properties and versatile applications. This article delves into the reasons why ceramic fiber fabric stands out as the best choice for safeguarding equipment and personnel from extreme heat and fire.

1. Exceptional High-Temperature Resistance

Ceramic fiber fabric is engineered to withstand extreme temperatures, often exceeding 1,600°C (2,912°F). This exceptional heat resistance makes it an ideal material for environments such as kilns, furnaces, and exhaust systems, where traditional insulation materials may fail. By providing reliable protection against extreme heat, ceramic fiber fabric ensures the safety and longevity of industrial equipment.

2. Outstanding Thermal Insulation Properties

One of the key benefits of ceramic fiber fabric is its remarkable thermal insulation capabilities. It effectively minimizes heat transfer, helping maintain optimal temperatures in various applications. This thermal efficiency is crucial for energy conservation, enabling industries to reduce operational costs while ensuring that processes run smoothly.

3. Fire-Resistant Characteristics

Ceramic fiber fabric is inherently fire-resistant and does not support combustion. This property significantly enhances safety in industrial settings, as it reduces the risk of fire hazards. With its ability to withstand direct flames and extreme heat, ceramic fiber fabric acts as a reliable barrier, protecting both equipment and personnel from potential fire incidents.

4. Lightweight and Flexible Design

Unlike traditional insulation materials that can be heavy and cumbersome, ceramic fiber fabric is lightweight and flexible. This design allows for easy handling and installation, making it a convenient choice for various applications. Its adaptability means it can conform to different shapes and sizes, ensuring comprehensive coverage and protection.

5. Chemical Resistance and Durability

Ceramic fiber fabric is resistant to a wide range of chemicals, making it suitable for diverse industrial environments. Its durability ensures that it maintains its structural integrity even in the presence of harsh chemicals, further enhancing its effectiveness in fire and heat protection. This resilience reduces the need for frequent replacements, making it a cost-effective choice for long-term use.

6. Versatile Applications Across Industries

The versatility of ceramic fiber fabric allows it to be used in numerous applications, including:

Insulation for High-Temperature Equipment: Protecting furnaces, boilers, and heat exchangers from heat loss.

Fire Blankets: Providing safety measures in welding and metalworking operations.

Protective Barriers: Shielding cables, hoses, and sensitive components from heat damage.

Its adaptability makes ceramic fiber fabric a preferred solution in various industries, including aerospace, automotive, manufacturing, and petrochemical.

7. Compliance with Safety Standards

Using ceramic fiber fabric helps organizations meet safety and environmental regulations. Its robust performance in fire and heat protection ensures compliance with industry standards, promoting a culture of safety within operations. This adherence to regulations is vital for maintaining operational integrity and minimizing liabilities.

8. Cost-Effectiveness and Long-Term Savings

Investing in ceramic fiber fabric can lead to significant cost savings over time. Its high durability and thermal efficiency reduce energy consumption and operational costs. Furthermore, the longevity of ceramic fiber fabric means fewer replacements are needed, enhancing its overall cost-effectiveness.