#Product Trends

How Is Ceramic Fiber Fabric Revolutionizing High-Temperature Insulation in Industrial Applications?

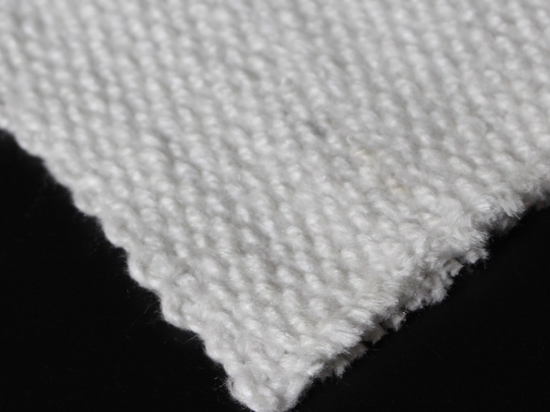

Ceramic Fiber Fabric

In the fast-paced world of industrial applications, effective thermal management is crucial for both safety and efficiency. Ceramic fiber fabric is at the forefront of this evolution, providing exceptional high-temperature insulation that meets the demanding needs of various industries. This article explores how ceramic fiber fabric is transforming the landscape of high-temperature insulation and why it is becoming a preferred choice among manufacturers and engineers.

1. Unmatched Temperature Resistance

Ceramic fiber fabric can withstand extreme temperatures, typically up to 1,600°C (2,912°F), making it ideal for high-temperature applications. This unparalleled heat resistance allows it to be used in various settings, from furnaces and kilns to exhaust systems and industrial boilers, where traditional insulation materials might fail.

2. Superior Thermal Insulation Properties

The innovative structure of ceramic fiber fabric provides excellent thermal insulation, reducing heat transfer and maintaining optimal operating conditions. By minimizing heat loss, it enhances the overall energy efficiency of industrial processes. This insulation capability is crucial for industries such as aerospace, automotive, and manufacturing, where heat management is essential for performance and safety.

3. Lightweight and Flexible Design

One of the most significant advantages of ceramic fiber fabric is its lightweight and flexible nature. Unlike traditional insulation materials that can be bulky and cumbersome, ceramic fiber fabric is easy to handle and install. Its flexibility allows it to conform to various shapes and sizes, ensuring comprehensive coverage and protection for equipment in diverse applications.

4. Fire Resistance for Enhanced Safety

Safety is a top priority in any industrial environment. Ceramic fiber fabric is inherently fire-resistant and does not support combustion, significantly reducing the risk of fire hazards. This characteristic makes it an invaluable component in high-temperature settings, providing peace of mind to manufacturers and workers alike.

5. Chemical and Abrasion Resistance

In many industrial applications, exposure to harsh chemicals and abrasive materials is a common concern. Ceramic fiber fabric is resistant to a wide range of chemicals, ensuring that it maintains its integrity and insulation properties even in challenging environments. This durability enhances its effectiveness in protecting equipment from heat and other detrimental factors.

6. Versatile Applications Across Industries

Ceramic fiber fabric's versatility allows it to be used in various applications, including thermal insulation for pipes, boilers, and furnaces, as well as protective barriers for high-temperature equipment. Its adaptability makes it suitable for industries such as petrochemical, metalworking, and power generation, where reliable thermal management is essential.

7. Compliance with Industry Standards

Using ceramic fiber fabric helps organizations comply with safety and environmental regulations. Its robust performance in high-temperature applications ensures that manufacturers meet stringent industry standards while promoting a culture of safety and responsibility within their operations.

8. Cost-Effective Solution for Long-Term Savings

Investing in ceramic fiber fabric can lead to significant long-term savings. Its durability and effectiveness in preventing heat loss reduce energy consumption and lower operational costs. Additionally, the long lifespan of ceramic fiber fabric minimizes the need for frequent replacements, further enhancing its cost-effectiveness.