#Product Trends

How Does Ceramic Fiber Sleeve Safeguard Equipment in Extreme Heat Environments?

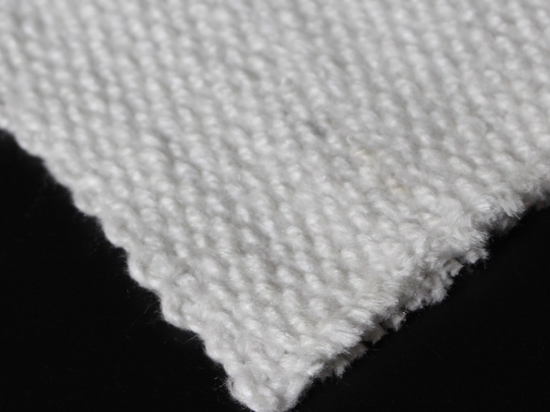

Ceramic Fiber Sleeve

In industries where equipment is regularly exposed to extreme heat, ensuring the protection of vital components is crucial. Ceramic fiber sleeves have emerged as a leading solution for safeguarding cables, hoses, and other equipment in high-temperature environments. This article delves into the ways ceramic fiber sleeves provide superior protection, enhancing both safety and performance.

1. Exceptional Heat Resistance

One of the most significant advantages of ceramic fiber sleeves is their ability to withstand extremely high temperatures. Capable of enduring temperatures up to 1,600°C (2,912°F), these sleeves are engineered to protect equipment from heat exposure. This high-temperature tolerance makes them ideal for use in industries such as aerospace, automotive, and manufacturing, where equipment often operates under challenging thermal conditions.

2. Effective Insulation Properties

Ceramic fiber sleeves offer excellent thermal insulation, minimizing heat transfer to surrounding components. This insulation capability protects sensitive cables and hoses from the damaging effects of heat, preventing premature wear and failure. By maintaining optimal operating temperatures, ceramic fiber sleeves help to enhance the overall efficiency and longevity of equipment, reducing the risk of overheating.

3. Fire Resistance for Enhanced Safety

In high-temperature applications, fire safety is a top priority. Ceramic fiber sleeves are inherently fire-resistant, meaning they do not support combustion. This characteristic is crucial for preventing potential fire hazards in environments where sparks or flames may occur. By utilizing ceramic fiber sleeves, businesses can create a safer workplace and mitigate the risks associated with high-temperature operations.

4. Chemical and Abrasion Resistance

Many industrial applications involve exposure to harsh chemicals and abrasive materials. Ceramic fiber sleeves exhibit exceptional resistance to a variety of corrosive substances, ensuring that they maintain their protective qualities over time. This chemical resilience allows for reliable insulation and safeguarding of cables and hoses, even in challenging conditions.

5. Lightweight and Flexible Design

Despite their robust protective properties, ceramic fiber sleeves are lightweight and flexible, making them easy to install and handle. Their flexibility allows them to conform to various shapes and sizes, ensuring a snug fit on different components. This adaptability enhances the effectiveness of the sleeve in protecting against heat and other environmental factors.

6. Durability and Long Lifespan

Ceramic fiber sleeves are designed for durability, which translates to long-lasting performance in extreme heat environments. Their robust construction reduces the need for frequent replacements, resulting in lower maintenance costs and increased operational efficiency. By investing in ceramic fiber sleeves, businesses can ensure their equipment remains protected for extended periods.

7. Versatile Applications Across Industries

Ceramic fiber sleeves are versatile and can be used in a wide range of applications, from automotive exhaust systems to aerospace components and industrial machinery. Their ability to provide reliable heat protection makes them suitable for various industries that require safeguarding equipment against extreme temperatures.

8. Compliance with Safety Standards

Using ceramic fiber sleeves helps organizations meet safety and regulatory standards in high-temperature environments. By protecting equipment from heat-related hazards, businesses can adhere to industry regulations and promote a culture of safety. Employees working with high-temperature equipment can feel secure knowing that robust protective measures are in place.