#Product Trends

Why Is Ceramic Fiber Sleeve the Ultimate Choice for High-Temperature Cable and Hose Protection?

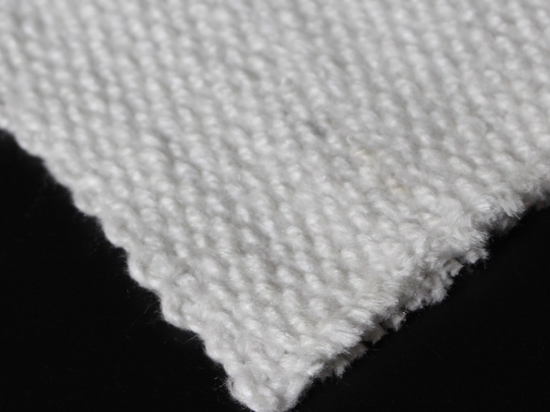

Ceramic Fiber Sleeve

In environments where extreme temperatures are a common challenge, protecting cables and hoses becomes paramount for safety and performance. Ceramic fiber sleeves have emerged as the ultimate solution for high-temperature applications, offering unparalleled protection and durability. This article explores the key reasons why ceramic fiber sleeves are the preferred choice for safeguarding vital components in various industries.

1. Superior Temperature Resistance

Ceramic fiber sleeves are designed to withstand extreme temperatures, with some products capable of enduring heat up to 1,600°C (2,912°F). This exceptional heat resistance makes them ideal for applications in industries such as aerospace, automotive, and manufacturing, where exposure to high temperatures is inevitable. By using ceramic fiber sleeves, businesses can ensure their cables and hoses remain intact and functional, even in the most demanding environments.

2. Excellent Insulation Properties

One of the standout features of ceramic fiber sleeves is their remarkable insulation capabilities. These sleeves are constructed from high-quality ceramic fibers that minimize heat transfer, protecting the inner components from the intense heat of surrounding equipment. By maintaining optimal operating temperatures, ceramic fiber sleeves help enhance the overall efficiency of systems and reduce the risk of heat-related failures.

3. Fire-Resistant Design

In high-temperature applications, fire safety is a critical concern. Ceramic fiber sleeves are inherently fire-resistant, meaning they will not support combustion. This characteristic is vital for protecting cables and hoses from flames and sparks, contributing to a safer work environment. By incorporating ceramic fiber sleeves into their systems, companies can significantly lower the risk of fire-related incidents.

4. Chemical Resistance

Industrial settings often expose materials to harsh chemicals and corrosive substances. Ceramic fiber sleeves exhibit excellent resistance to a variety of chemicals, including acids, alkalis, and solvents. This chemical resilience ensures that the sleeves maintain their protective properties over time, providing reliable insulation and protection for cables and hoses.

5. Lightweight and Flexible

Despite their robust performance, ceramic fiber sleeves are surprisingly lightweight and flexible. This makes them easy to handle and install, allowing for quick and efficient application on various components. The flexibility of ceramic fiber sleeves enables them to conform to different shapes and sizes, ensuring a snug fit that enhances protection.

6. Durability and Longevity

Ceramic fiber sleeves are designed for long-lasting performance, making them a cost-effective choice for high-temperature applications. Their durability means less frequent replacements, resulting in lower maintenance costs over time. By investing in ceramic fiber sleeves, businesses can enhance their operational efficiency and reduce downtime caused by equipment failures.

7. Enhanced Safety and Compliance

Using ceramic fiber sleeves helps organizations meet safety and compliance standards in high-temperature environments. These sleeves protect against potential hazards such as heat exposure and fire, ensuring that businesses adhere to industry regulations and promote a culture of safety. Employees working with or around high-temperature equipment can feel more secure knowing that robust protective measures are in place.

8. Versatile Applications

Ceramic fiber sleeves are versatile and can be used in a wide range of applications, including automotive exhaust systems, aerospace components, industrial machinery, and more. Their ability to withstand high temperatures and resist fire makes them suitable for diverse industries that require reliable heat protection for cables and hoses.