#Product Trends

How Does Ceramic Fiber Tape Excel in High-Temperature Sealing and Insulation?

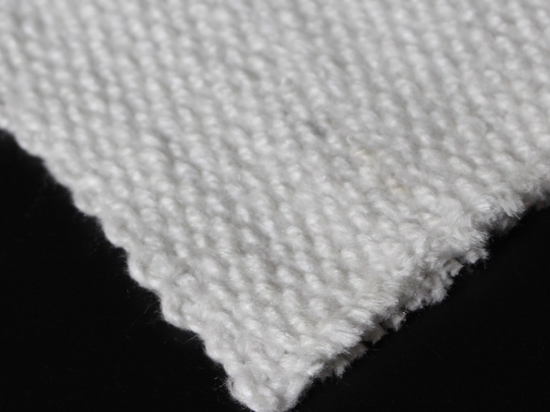

Ceramic Fiber Tape

In industries where high temperatures are a constant challenge, reliable sealing and insulation materials are essential for maintaining safety and performance. Ceramic fiber tape has emerged as a leading choice for high-temperature applications, offering a range of benefits that enhance both insulation and sealing capabilities. This article explores how ceramic fiber tape excels in high-temperature environments, making it an invaluable tool for various industries.

1. Exceptional Temperature Resistance

One of the standout features of ceramic fiber tape is its remarkable temperature resistance. Capable of withstanding temperatures up to 1,600°C (2,912°F), ceramic fiber tape provides unparalleled protection against heat. This high-temperature capability makes it ideal for applications in industries such as aerospace, automotive, and manufacturing, where equipment and components are frequently exposed to extreme heat. By using ceramic fiber tape, operators can prevent heat-related failures and ensure the longevity of critical systems.

2. Effective Insulation Properties

Ceramic fiber tape is designed to offer excellent thermal insulation, helping to minimize heat transfer and maintain optimal operating conditions. Its low thermal conductivity ensures that heat is contained within designated areas, protecting sensitive components from overheating and reducing energy loss. This insulation capability is particularly beneficial in applications involving furnaces, kilns, and boilers, where maintaining consistent temperatures is vital for efficiency and safety.

3. Superior Sealing Capabilities

In addition to its insulation properties, ceramic fiber tape excels at sealing joints and gaps in high-temperature applications. Its flexibility and conformability allow it to fit securely around irregular surfaces, creating a tight seal that prevents the escape of heat and gases. This sealing capability is crucial in environments where maintaining pressure and preventing leaks are essential for operational efficiency and safety.

4. Chemical Resistance

Ceramic fiber tape is highly resistant to various chemicals, including acids, alkalis, and solvents. This resistance is important in industrial settings where exposure to harsh substances is common. By using ceramic fiber tape, operators can protect their equipment from chemical degradation while ensuring that sealing and insulation properties remain intact. This durability contributes to the overall effectiveness of the tape in challenging environments.

5. Lightweight and Easy to Handle

Despite its robust performance characteristics, ceramic fiber tape is lightweight and easy to handle. This feature simplifies installation and application, allowing technicians to work efficiently even in challenging conditions. The lightweight nature of the tape ensures that it does not add significant bulk to the components it covers, maintaining the overall design integrity of equipment and systems.

6. Versatile Applications

Ceramic fiber tape is incredibly versatile, making it suitable for a wide range of applications across various industries. Whether used for sealing exhaust systems, insulating pipelines, or protecting components in high-temperature furnaces, ceramic fiber tape can be tailored to meet specific needs. Its adaptability ensures that it delivers effective performance in diverse settings, enhancing its value as a protective material.

7. Cost-Effective Solution

While the initial investment in ceramic fiber tape may be higher than some conventional sealing and insulation materials, its long-term benefits justify the cost. The tape’s durability, high-temperature resistance, and chemical resilience lead to reduced maintenance and replacement expenses over time. By preventing heat loss and minimizing the risk of equipment failure, ceramic fiber tape offers a cost-effective solution for high-temperature applications.