#Product Trends

Versatile Applications of Ceramic Insulation Fabric

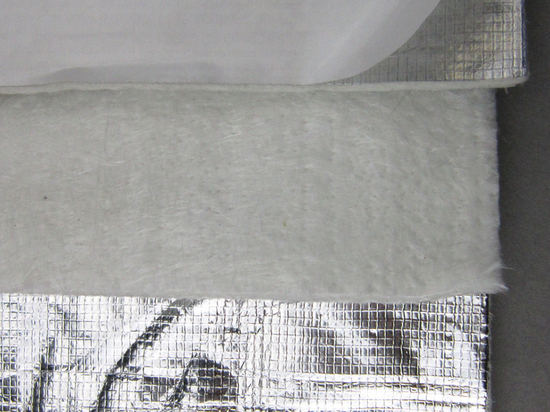

Ceramic Insulation Fabric

Ceramic Insulation Fabric is a highly advanced thermal protection solution designed to meet the rigorous demands of various industries. Crafted from high-purity ceramic fibers, this fabric provides exceptional heat resistance, capable of withstanding temperatures up to 2,300°F (1,260°C). Its versatility makes it an essential component for a wide range of applications, enhancing safety and efficiency across multiple sectors.

In the automotive industry, Ceramic Insulation Fabric plays a crucial role in thermal management. It is commonly used to insulate exhaust systems, protecting surrounding components from extreme heat and preventing potential damage. By maintaining optimal temperatures, this fabric enhances vehicle performance and reliability, ensuring longevity in high-stress environments. Additionally, it can be utilized for thermal barriers in turbochargers, safeguarding sensitive electronics and improving overall engine efficiency.

The aerospace sector significantly benefits from the properties of Ceramic Insulation Fabric. This fabric is essential for insulating critical components in aircraft, including wiring and electronic systems, shielding them from the high temperatures generated during flight operations. Its lightweight design ensures that it does not compromise the overall weight of the aircraft, making it an ideal choice for maintaining optimal performance and safety standards in aviation.

In industrial applications, Ceramic Insulation Fabric is invaluable for protecting equipment and personnel from extreme heat and fire hazards. It is often used in manufacturing facilities to insulate pipes, valves, and tanks, preventing heat loss and ensuring that processes operate efficiently. This fabric also provides effective thermal protection in welding and metal fabrication environments, where it acts as a barrier against sparks and molten metal.

The marine industry employs Ceramic Insulation Fabric for thermal protection in engine compartments and exhaust systems. This fabric helps maintain safe operating temperatures, enhancing the efficiency and reliability of marine vessels. Its resistance to moisture and harsh marine conditions ensures durability, making it a trusted solution for shipbuilders and operators.

Furthermore, Ceramic Insulation Fabric is essential in fire protection applications. It can be used to wrap critical structural components in buildings, enhancing fire resistance and protecting lives and property in the event of a fire. Its exceptional thermal stability provides peace of mind for architects and builders, ensuring compliance with stringent safety regulations.

The fabric's flexibility and ease of installation further enhance its appeal. It can be cut and shaped to fit various applications, allowing for seamless integration into existing systems without the need for extensive modifications. This user-friendly characteristic ensures quick deployment, minimizing downtime and enhancing productivity in manufacturing and construction projects.

In conclusion, Ceramic Insulation Fabric stands out as a versatile and high-performance solution for thermal management across diverse applications. Its remarkable heat resistance, durability, and adaptability make it an essential asset for industries aiming to enhance safety, efficiency, and operational reliability. Embrace the transformative potential of Ceramic Insulation Fabric and elevate your thermal protection strategy to meet the challenges of modern engineering.