#Product Trends

Silicone fiberglass Fire Protection Sleeve used for hydraulic hose heat protection

Fire Protection Sleeve

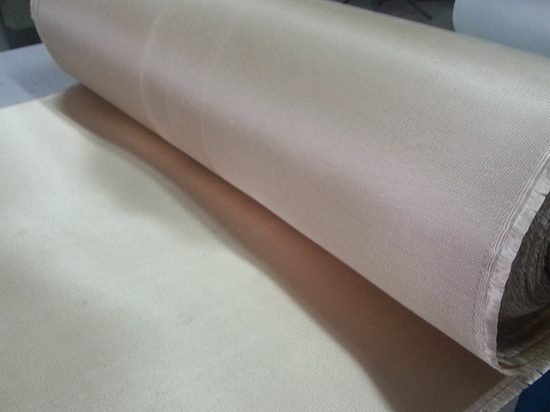

A Silicone Fiberglass Fire Protection Sleeve is a specialized protective covering designed to shield hydraulic hoses and other flexible lines from extreme heat, flame, and thermal damage. It's commonly used in industries where hydraulic systems are exposed to high temperatures, such as in automotive, aerospace, manufacturing, and heavy equipment.

Here's a breakdown of the key features and benefits:

Key Features:

Material Composition:

Fiberglass Base: The sleeve is primarily made from woven fiberglass, which offers excellent thermal insulation and high heat resistance.

Silicone Coating: A silicone rubber coating is applied to the fiberglass material. This provides additional heat resistance, flexibility, and protection against environmental elements like water, oil, and chemicals.

Heat Resistance:

Silicone fiberglass sleeves can withstand temperatures ranging from -70°C to +250°C (-94°F to +482°F) depending on the specific product, and some can handle even higher temperatures in short bursts. This makes them ideal for applications with high heat exposure.

Fire Protection:

The sleeve offers fire resistance, helping to prevent flames from reaching sensitive hydraulic hoses or cables in the event of a fire or heat source. In some cases, the silicone coating can be flame-retardant, providing an added layer of protection.

Abrasion Resistance:

The woven fiberglass structure is durable and can provide a degree of abrasion resistance, preventing physical wear and tear from mechanical movement or friction.

Chemical and Environmental Resistance:

The silicone coating also enhances the sleeve's resistance to oils, fuels, and various chemicals, making it suitable for demanding industrial environments where exposure to aggressive substances is common.

Flexibility and Easy Installation:

Silicone fiberglass sleeves are flexible and easy to install around hydraulic hoses, wiring, or cables, even in tight spaces. They can be cut to the desired length and installed without the need for special tools.

Applications:

Hydraulic Systems: Protects hydraulic hoses from heat and fire, which is especially important in environments like high-performance engines, industrial machinery, and heavy equipment.

Automotive and Racing: Used in race cars, trucks, and other vehicles where heat management is critical, protecting hoses and wires from engine heat, exhaust gases, or fire.

Aerospace: Applied to aircraft hydraulic lines and cables to ensure safe operation in high-heat zones such as near engines or exhaust areas.

Marine and Offshore: Protects hoses and wiring exposed to high heat, flame, and corrosive environments, such as in engine rooms, exhaust systems, or industrial marine applications.

Advantages:

Enhanced Safety: Helps prevent hose failure due to overheating or fire exposure.

Extended Hose Life: Protects hoses from heat degradation, reducing the need for frequent replacements.

Improved System Performance: Ensures hydraulic hoses operate within safe temperature limits, optimizing the performance of the system.

Cost-Effective Solution: By extending the life of hoses and reducing the risk of fire damage, the need for costly repairs or replacements is minimized.

Installation Tips:

Ensure the sleeve fits snugly over the hose and is secured in place. Some sleeves come with Velcro or fastening systems for easy installation.

In some cases, a high-temperature adhesive may be used at the ends to keep the sleeve from shifting or unraveling.

Avoid pulling the sleeve too tight, as it may compromise its flexibility and protective properties.

In summary, silicone fiberglass fire protection sleeves are an essential component for protecting hydraulic hoses in high-temperature or fire-prone environments, offering a combination of heat resistance, flame protection, and durability.