#Product Trends

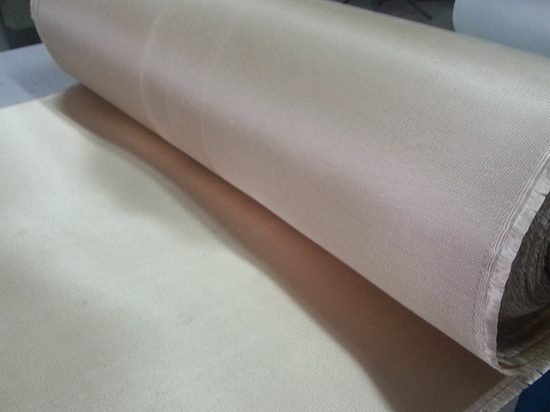

Hose Protective Fire Sleeve

Fire Sleeve

A Hose Protective Fire Sleeve is a high-performance, heat-resistant covering designed to protect hoses, cables, and wires from extreme temperatures, flames, and mechanical damage. Constructed from materials such as fiberglass, silicone-coated fabrics, or braided fiberglass, these sleeves provide a reliable barrier against heat, abrasion, sparks, and fire. They are commonly used in industries where hoses and cables are exposed to high heat or dangerous conditions, including automotive, aerospace, firefighting, and manufacturing.

The primary function of a fire sleeve is to prevent damage to vital equipment by insulating it from heat sources. This is especially important in environments where high-temperature fluids or gases are transported through hoses, as well as in situations where hoses or cables could be exposed to flames or intense radiant heat. The protective sleeve significantly extends the life of the hose or cable by reducing wear and tear caused by thermal exposure and physical abrasion.

In addition to heat resistance, fire sleeves are often designed to be flexible, making them easy to install and maintain. They also provide protection against chemical exposure and can resist certain oils and solvents. Some fire sleeves are even rated to withstand temperatures of up to 1,000°F (537°C) or higher, depending on the material used.

Overall, Hose Protective Fire Sleeves are an essential safety and maintenance solution, helping to ensure the reliability and longevity of equipment in demanding environments. By providing thermal protection and reducing the risk of equipment failure, these sleeves contribute to both safety and operational efficiency in various industrial applications.