#Product Trends

What is the application of aluminum coated fiberglass sleeving?

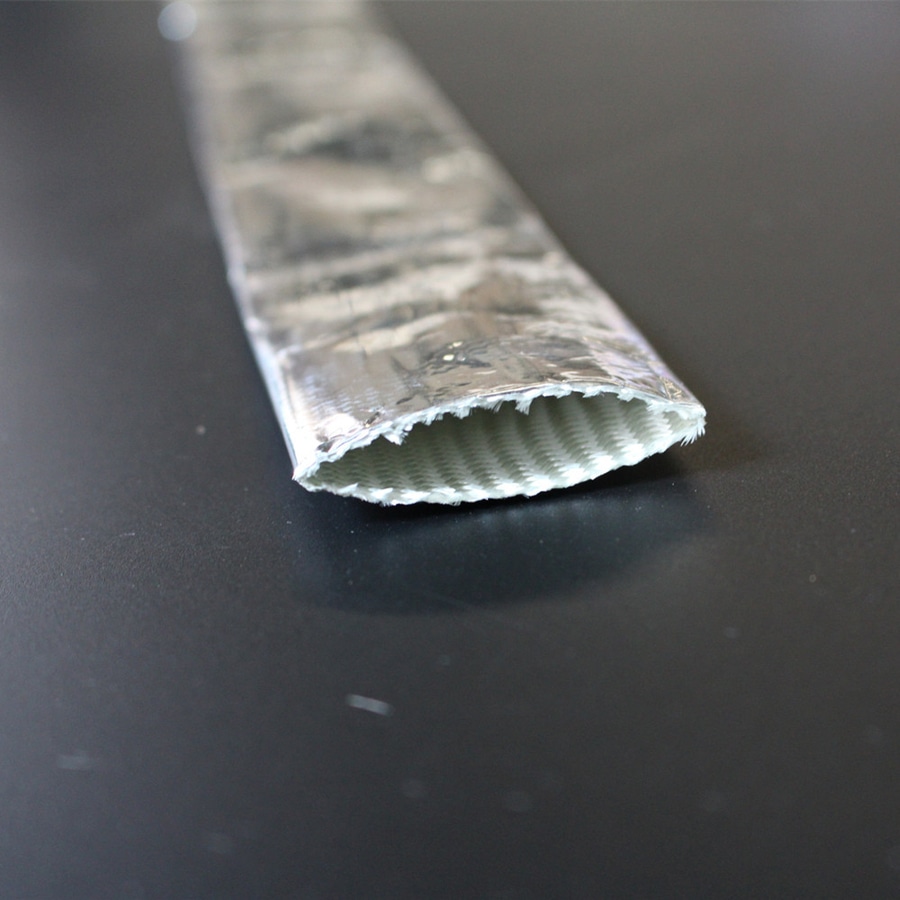

aluminum coated fiberglass sleeving

Aluminum coated fiberglass sleeving is a versatile and highly effective thermal protection material with a range of applications. Its primary function is to provide thermal insulation and protect components from heat, abrasion, and environmental damage. The aluminum coating enhances the material’s reflective properties, making it effective in applications where heat resistance and durability are crucial.

Common Applications:

Automotive and Racing Industry:

Exhaust systems: Protects wires, hoses, and cables from extreme temperatures near the exhaust manifold or pipes.

Turbochargers: Used to insulate sensitive components from the intense heat generated by turbochargers.

Engine compartments: Helps to reduce heat soak, keeping electrical systems, wiring, and hoses safe from damage in high-temperature environments.

Aerospace:

Wiring protection: Protects wiring in aircraft from high temperatures, ensuring electrical integrity and preventing insulation breakdown.

Thermal shielding: Applied to various parts of the aircraft to maintain optimal temperatures and prevent heat damage to critical components.

Industrial Applications:

Manufacturing machinery: Shields cables and wires near hot surfaces, such as furnaces, kilns, or industrial ovens.

Power plants: Used for insulation in high-temperature areas to protect cables and wires from excessive heat.

Marine:

Marine engine compartments: Prevents heat damage to wires and hoses, particularly in engine rooms where high temperatures are prevalent.

Exhaust systems and turbocharger protection: Ensures cables and hoses are protected in the high-heat environment of marine engines.

Electrical and Electronics:

Cable insulation: Protects cables from heat and mechanical damage, ensuring longer lifespan and preventing electrical faults.

Heat-sensitive equipment: Used to insulate sensitive electronics and electrical components from heat in industrial, automotive, and electronic applications.

Military and Defense:

Thermal protection: Applied to wires and components in high-heat areas, such as military vehicles, ensuring operational reliability in extreme conditions.

Tactical equipment: Protects wiring and other sensitive parts in military machinery from heat-induced wear.

Benefits:

Heat Resistance: Withstands high temperatures (up to 800°F or 425°C) due to the combination of fiberglass and aluminum coating.

Reflective Properties: The aluminum coating reflects heat, which helps in reducing the heat exposure to underlying components.

Abrasion Resistance: Protects against physical wear and tear, ensuring longer durability in harsh environments.

Lightweight: While highly protective, it does not add significant weight to the components it's used on.

Flexibility: It can be easily installed over cables, wires, and hoses without requiring disassembly of existing systems.

Aluminum-coated fiberglass sleeving is an excellent solution for applications requiring high-performance insulation, heat reflection, and protection in extreme environments.