#Product Trends

What is Hydraulic Hose Protection?

Hydraulic Hose Protection

Hydraulic hose protection refers to the use of various materials, devices, or techniques designed to safeguard hydraulic hoses and related components from damage, wear, and external hazards. Hydraulic hoses are crucial components in fluid power systems, transmitting pressurized fluids to power machinery or equipment. However, they are vulnerable to various forms of damage that can cause leaks, system failure, or unsafe working conditions. Protection measures help extend the life of these hoses, improve operational efficiency, and reduce downtime or maintenance costs.

Key Aspects of Hydraulic Hose Protection:

Abrasion Resistance:

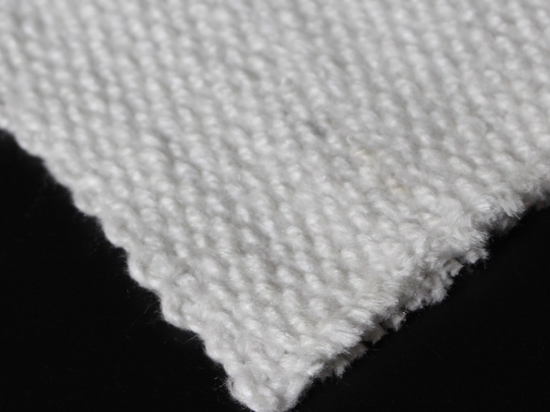

Hydraulic hoses are exposed to rough surfaces, sharp edges, and constant movement that can cause abrasion over time. Protective sleeves, wraps, or covers made from materials like braided nylon, fiberglass, Kevlar, or plastic spirals shield hoses from abrasive surfaces.

UV and Environmental Protection:

Exposure to ultraviolet (UV) rays, extreme temperatures, chemicals, and weather conditions can degrade hoses. Protective coatings, wraps, and jackets prevent UV degradation, cracking, or weakening of the hose material.

Thermal Protection:

Hydraulic systems often operate in high-temperature environments. Protective sleeves or wraps made from heat-resistant materials (like silicone-coated fiberglass, ceramic fiber, or aluminized fabrics) can insulate hoses from excessive heat and prevent premature failure due to overheating.

Impact and Mechanical Damage:

Hydraulic hoses often face impact damage from machinery, moving parts, or environmental factors. Protective devices such as spiral wound guards, tubular sleeves, and braided steel wraps absorb or deflect impacts, preventing punctures and cuts.

Chemical Resistance:

Exposure to harsh chemicals, oils, or fuels can weaken hydraulic hoses over time. Protective covers made from chemical-resistant fabrics or plastic coatings safeguard hoses from corrosive substances and prevent degradation.

Burst and Leakage Prevention:

In case of hose bursts, a protective sleeve can contain the fluid and prevent dangerous splashing or leakage. Specialized hydraulic hose burst sleeves can help contain leaks, directing the fluid safely and preventing harm to nearby equipment or personnel.

Common Types of Hydraulic Hose Protection:

Protective Sleeves & Covers: These are often used to shield hoses from abrasion, UV exposure, and minor impacts. Made from materials such as nylon, polyester, or fiberglass, they can be easily installed around the hose.

Spiral Wraps & Tubular Guards: Spiral wraps, typically made from durable plastic or metal, provide flexible protection that wraps around the hose to prevent wear. Tubular guards offer similar benefits with additional protection against environmental factors.

Thermal Insulation: Used when hoses are exposed to extreme heat, these materials provide high-temperature resistance and prevent the hose from overheating.

End Fittings & Caps: These are used to protect the ends of hydraulic hoses during storage, handling, and transportation to prevent damage to connectors or fittings.

Benefits of Hydraulic Hose Protection:

Extended Hose Life: Protection reduces wear and tear, minimizing the need for costly replacements.

Increased Safety: Reduces the risk of leaks, bursts, and system failures, protecting both operators and equipment.

Reduced Maintenance Costs: By preventing damage and extending the life of hoses, protection reduces the frequency and cost of repairs.

Improved Efficiency: Well-maintained hoses perform more effectively, keeping systems running smoothly and without interruption.

In summary, hydraulic hose protection is an essential part of maintaining the integrity and efficiency of hydraulic systems. It shields hoses from environmental damage, wear, and potential hazards, ensuring the system operates safely and reliably.