#Product Trends

Burst Protection Sleeving for Hydraulic Hoses

Burst Protection Sleeving

Hydraulic hoses are critical components in industrial systems, subject to extreme pressures and heavy-duty environments. Even the smallest compromise can lead to catastrophic failures, creating risks of fluid leaks, equipment downtime, and costly repairs. That’s where Burst Protection Sleeving for hydraulic hoses steps in, offering a vital safeguard for your hydraulic systems.

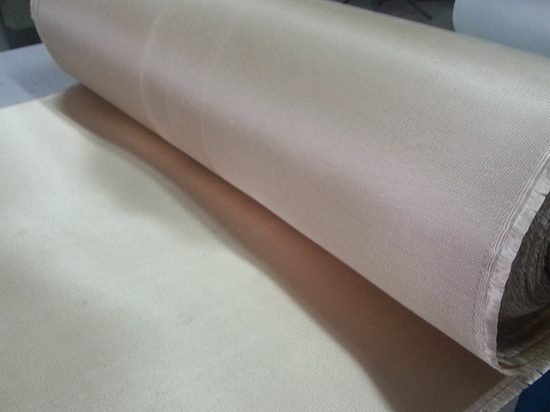

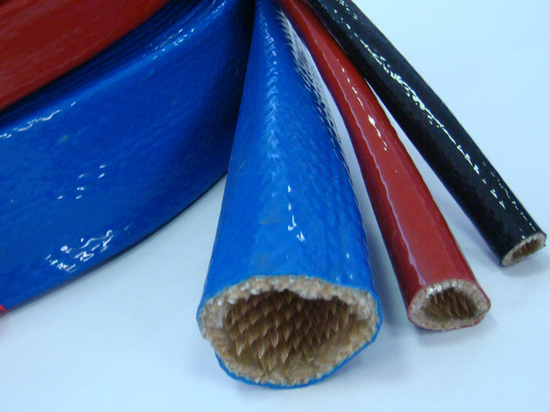

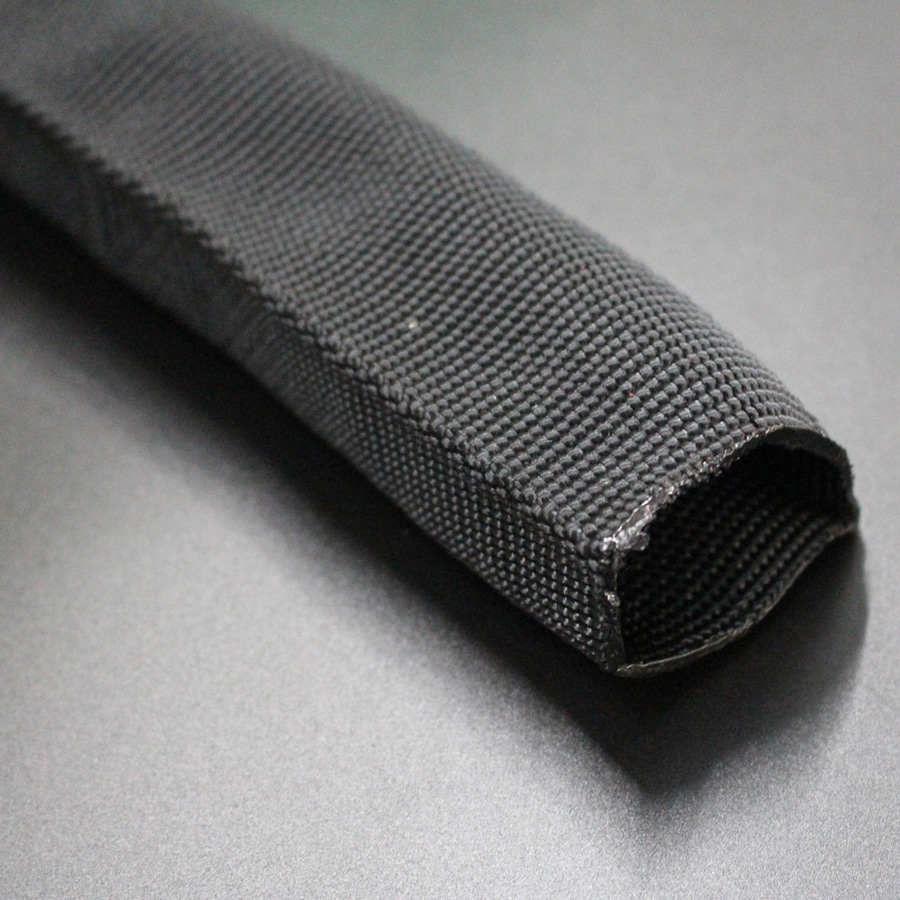

Our Burst Protection Sleeving is designed to contain and control high-pressure bursts, preventing leaks and minimizing the risks associated with sudden hydraulic failures. Made from robust materials like high-strength Kevlar, nylon, or stainless steel, the sleeving is engineered to absorb pressure, withstand abrasion, and protect against external impacts.

Key Features:

High-Pressure Resistance: Built to withstand the most demanding applications, our sleeving offers superior protection against hydraulic burst pressures, safeguarding both hoses and surrounding environments.

Durability: Constructed from strong, abrasion-resistant fibers, the burst protection sleeving can endure harsh operational conditions, including exposure to oils, solvents, and extreme temperatures.

Versatility: Ideal for a wide range of hydraulic systems, including automotive, heavy machinery, aerospace, and industrial machinery. Whether you're working with high-flow or high-pressure systems, our sleeving adapts to various hose sizes and pressure ratings.

Prevents Spills & Contamination: In the event of a burst, the protective sleeve contains the pressurized fluid, minimizing potential contamination risks to the surrounding environment and reducing workplace hazards.

Ease of Installation: Designed for straightforward application, our sleeving can be cut to size and installed without the need to disconnect or disassemble the hydraulic system.

Real-World Applications:

Heavy Equipment & Construction: Hydraulic hoses on bulldozers, cranes, and excavators are prone to high-pressure bursts under continuous heavy usage. Burst protection sleeving helps mitigate the risk of accidents on-site.

Automotive & Racing: In high-performance vehicles, where hydraulic systems are under immense stress, sleeving protects hoses from burst failures, ensuring safety during high-speed maneuvers.

Aerospace: Aircraft hydraulic lines are subjected to extreme conditions; burst protection sleeving provides an added layer of defense against pressure surges that could compromise system integrity.

Manufacturing & Industrial Systems: Hydraulic systems in manufacturing equipment often operate at high pressures. Burst protection sleeving ensures operational reliability by protecting critical components from sudden bursts.

Why Choose Our Burst Protection Sleeving?

Reliability: Built to meet or exceed industry standards, our sleeves offer long-term protection, reducing the risk of failure and costly downtime.

Customizable Fit: Available in various sizes and materials, our sleeving is tailored to fit your specific application, whether you require protection for small hoses or large, high-pressure lines.

Cost-Effective Safety: Investing in burst protection sleeving is an affordable way to enhance the safety and longevity of your hydraulic systems while reducing the potential for fluid leaks and associated damage.

With Burst Protection Sleeving for Hydraulic Hoses, you're investing in more than just a protective layer—you're securing the safety, efficiency, and longevity of your equipment. Ensure your hydraulic systems are shielded from the risk of failure and keep your operations running smoothly, no matter the pressure.