#Product Trends

Why the hydraulic hose protective fire sleeve can resistant high temperature?

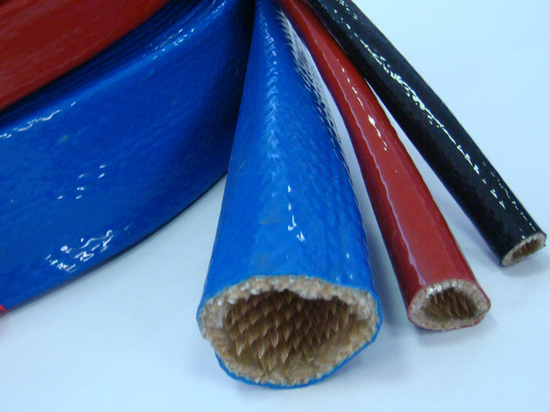

hydraulic hose protective fire sleeve

The hydraulic hose protective fire sleeve is designed to resist high temperatures through the use of advanced materials and construction methods that provide superior heat protection. Here’s why it’s so effective:

1. Heat-Resistant Materials:

The sleeve is typically made from materials like silicone rubber, fiberglass, or a combination of both. These materials are inherently heat-resistant and can withstand extreme temperatures without degrading. Fiberglass can tolerate temperatures up to 1,000°C (1,832°F), while silicone rubber can endure continuous high temperatures up to 250°C (482°F), and even higher in short bursts.

2. Thermal Insulation:

The fire sleeve often incorporates a layer of thermal insulation, which creates a barrier between the hose and the external heat source. This insulation helps to maintain the integrity of the hydraulic hose by preventing heat from transferring through the sleeve and affecting the hose material, thereby reducing the risk of hose degradation due to high temperatures.

3. Multi-Layer Construction:

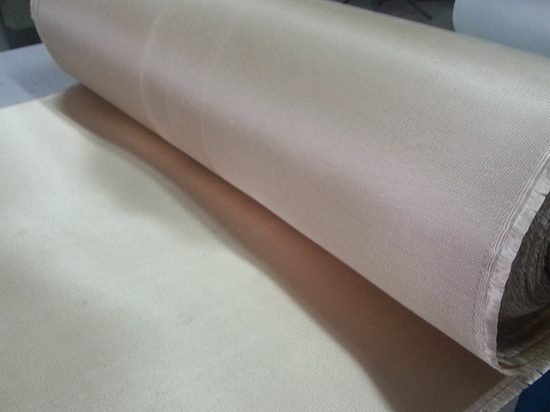

Many fire sleeves are made with a multi-layered design, combining a heat-resistant outer layer (often silicone-coated fiberglass) with an inner layer of fabric or rubber. This layering improves the sleeve's overall heat resistance by providing multiple barriers to thermal conductivity, ensuring that even extreme heat doesn’t reach the hose inside.

4. Heat Reflectivity:

The outer layer of the fire sleeve, often made of fiberglass or aluminum-coated fabrics, reflects and dissipates heat, reducing the amount of heat that is absorbed by the hose. This helps protect the hydraulic hose from direct exposure to flames, molten splashes, or other heat sources.

5. Fire Resistance and Flame Retardancy:

Fire sleeves are designed to be flame-retardant, meaning they will not catch fire easily and can withstand exposure to open flames for extended periods. This property is especially important in industries like automotive, aerospace, and manufacturing, where hydraulic hoses may come into contact with high-temperature sources or fire hazards.

6. Durable Fiber Construction:

The fibers used in the construction of the fire sleeve, such as fiberglass, have excellent high-temperature stability and can maintain their structural integrity even under extreme heat. Unlike other materials that may weaken or degrade when exposed to high temperatures, fiberglass maintains its shape and strength, providing ongoing protection to the hydraulic hose.

7. Flexibility Under Heat:

Despite its high-temperature resistance, the fire sleeve remains flexible and does not become brittle. This flexibility ensures that it can continue to offer reliable protection even when exposed to both high heat and mechanical stress, such as movement or vibration in hydraulic systems.