#Product Trends

What is aluminized fiberglass fabric? What is it used for and what is the benifit?

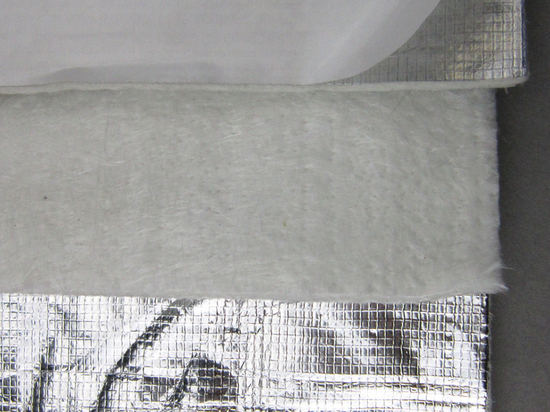

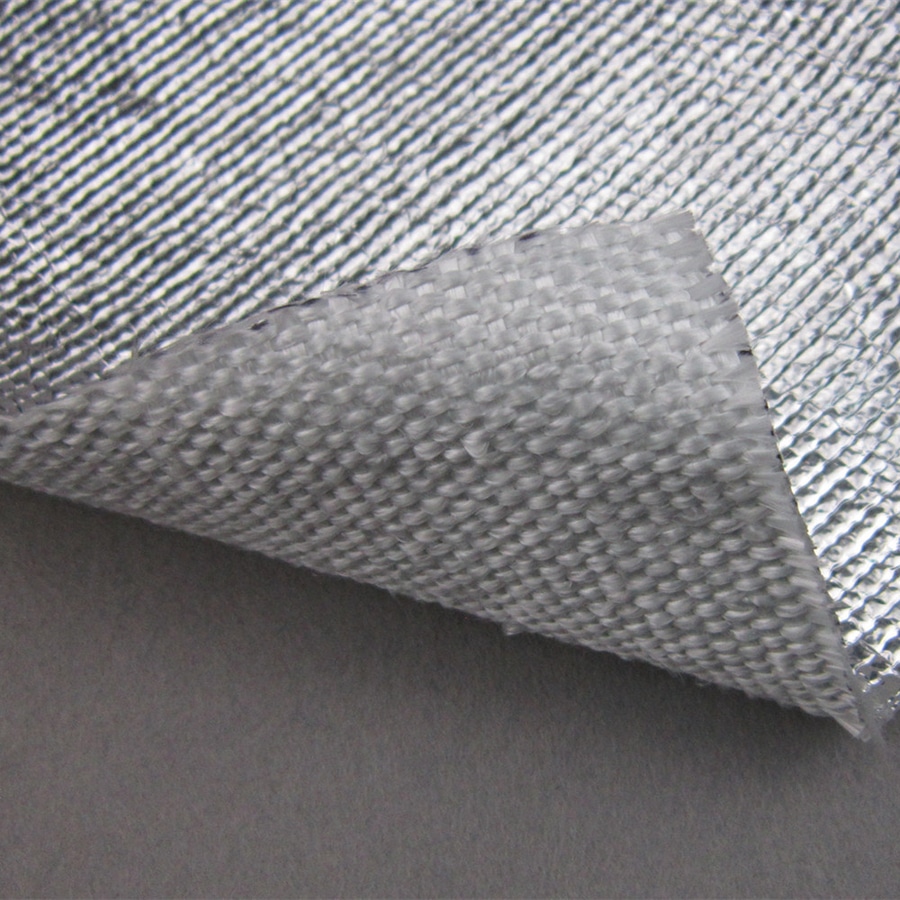

aluminized fiberglass fabric

Aluminized Fiberglass Fabric is a type of heat-resistant fabric made from fiberglass fibers that are coated with a thin layer of aluminum foil. The fiberglass provides excellent strength and heat resistance, while the aluminum coating adds reflective properties, significantly enhancing its ability to reflect and dissipate heat. This fabric is widely used in applications where high-temperature resistance and thermal insulation are essential.

Key Properties of Aluminized Fiberglass Fabric:

High Temperature Resistance:

The fiberglass base can withstand extremely high temperatures, often up to 550°C (1,022°F) or higher, depending on the specific material. The aluminum coating further extends its thermal protection, enabling the fabric to perform in high-heat environments.

Heat Reflection:

The aluminum layer reflects a significant amount of heat, reducing the amount of heat absorbed by the fabric and the components it protects. This reflective property makes aluminized fiberglass fabric highly effective for reducing heat transfer in both hot and cold environments.

Durability and Strength:

Fiberglass is known for its strength, providing a tough, abrasion-resistant material that maintains its structural integrity even under harsh conditions. The fabric is flexible but strong, able to resist wear and tear in demanding environments.

Fire-Resistant:

Both the fiberglass and aluminum materials are non-combustible, making the fabric inherently fire-resistant. It provides an additional layer of protection in environments where flames or sparks may be present.

Lightweight:

Despite its strength and heat resistance, aluminized fiberglass fabric is lightweight, which makes it easy to handle and apply in various applications without adding significant weight to the system.

Chemical Resistance:

The fabric is resistant to oils, acids, and other chemicals, making it suitable for use in environments where exposure to harsh substances is common.

Common Uses of Aluminized Fiberglass Fabric:

Heat Shields and Blankets:

Aluminized fiberglass fabric is commonly used to make heat shields and thermal blankets to protect machinery, workers, and sensitive equipment from excessive heat. This is particularly useful in industries like automotive, aerospace, and oil and gas.

Exhaust Insulation:

The fabric is widely used for insulating exhaust systems in automotive, marine, and industrial applications. The reflective aluminum layer helps reduce the heat radiating from exhaust pipes and mufflers, preventing heat damage to surrounding components and improving system efficiency.

Welding and Fire Protection:

In industries like welding, the fabric is used as a protective cover or curtain to shield workers and equipment from sparks, molten metal splashes, and extreme heat. It is commonly used in welding blankets to create a fireproof barrier.

Protecting Hydraulic Hoses and Cables:

Aluminized fiberglass fabric is often wrapped around hydraulic hoses, cables, and wires to provide thermal protection. The fabric prevents damage to hoses from hot surfaces and provides a heat-resistant barrier in environments where temperatures can reach dangerous levels.

Industrial Furnaces and Boilers:

The fabric is used to line industrial furnaces, kilns, and boilers, where it provides both thermal insulation and heat reflection. This helps improve energy efficiency and reduce heat loss in high-temperature processing environments.

Automotive and Aerospace Applications:

In the automotive industry, aluminized fiberglass fabric is used to protect critical engine parts, exhaust systems, and turbochargers from excessive heat. Similarly, in aerospace applications, it is used to insulate components exposed to extreme heat, such as engine parts, exhausts, and protective covers.

Thermal Insulation for Piping and Ducting:

The fabric is used to insulate pipes and ducts that carry hot fluids, gases, or air. By reflecting heat away from the system, it helps to maintain consistent temperatures and improve the overall energy efficiency of the system.

Benefits of Aluminized Fiberglass Fabric:

Superior Heat Protection:

The combination of fiberglass and aluminum provides superior thermal protection, making aluminized fiberglass fabric ideal for use in high-temperature environments. It helps shield equipment and components from extreme heat, preventing damage and ensuring operational safety.

Heat Reflection for Energy Efficiency:

The reflective aluminum coating helps reduce the amount of heat absorbed by surrounding materials. This not only protects components but also improves energy efficiency by reflecting heat away from the system, reducing the need for additional cooling measures.

Lightweight and Flexible:

Aluminized fiberglass fabric offers the right balance of flexibility and strength, making it easy to install and shape around complex components. It is lightweight, which makes it easier to handle compared to other high-temperature materials.

Fire Resistance:

The fabric is fireproof and non-combustible, providing an extra layer of protection in environments where sparks, open flames, or extreme heat are present. This makes it suitable for industries like welding, construction, and manufacturing.

Durability and Longevity:

The combination of fiberglass and aluminum ensures that the fabric is resistant to wear, abrasion, and physical damage. It offers long-lasting protection even in harsh operating conditions, making it a cost-effective solution for thermal protection.

Versatility:

Aluminized fiberglass fabric can be used in a wide range of applications, from protecting engine components and exhaust systems to insulating pipes, hoses, and cables. Its versatility makes it an essential material in industries such as automotive, aerospace, chemical processing, and manufacturing.

Chemical and Environmental Resistance:

The fabric resists a variety of harsh chemicals, oils, and solvents, making it a reliable choice for industrial applications. It can also withstand exposure to UV light, moisture, and other environmental factors, increasing its longevity in outdoor or corrosive environments.