#Product Trends

What is the Industry Trends of aluminized fiberglass fabric?

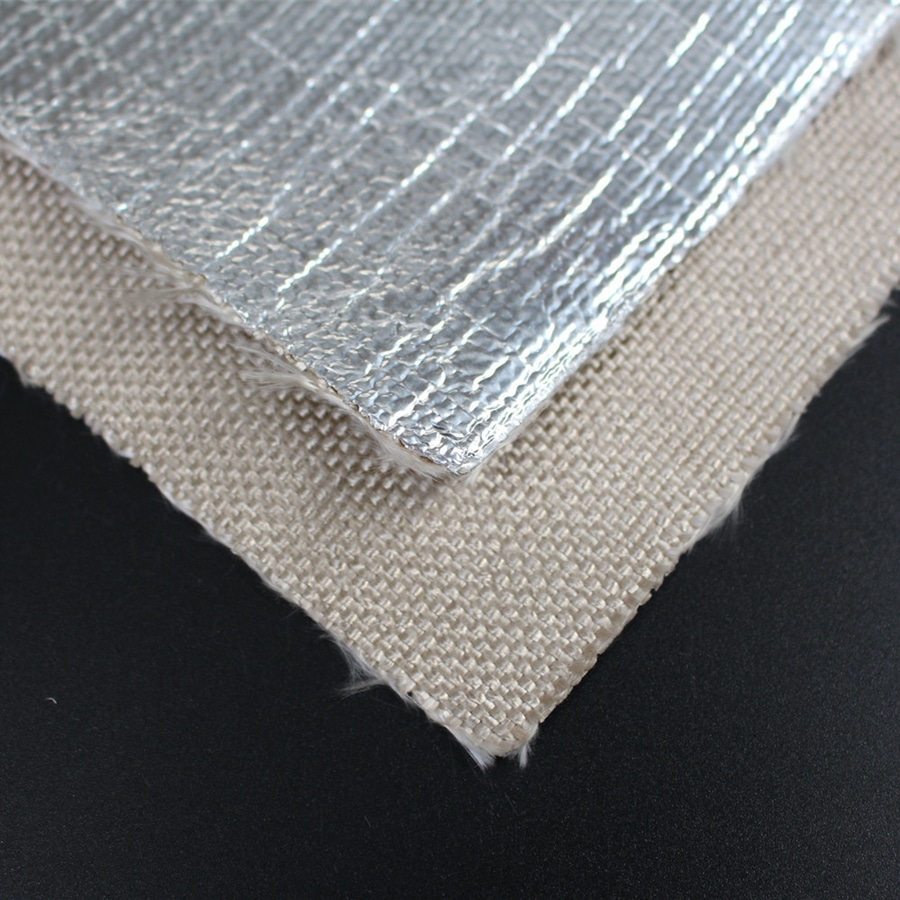

aluminized fiberglass fabric

The industry trends for aluminized fiberglass fabric are driven by increasing demand for high-performance, heat-resistant, and durable materials in various applications. Key trends include:

Enhanced Thermal Protection: Aluminized fiberglass fabric is increasingly used in industries that require superior heat resistance, such as automotive, aerospace, and manufacturing. The aluminum coating provides enhanced thermal insulation, reflecting heat and reducing the risk of damage to sensitive components.

Fire Safety and Protection: As fire safety regulations become more stringent, aluminized fiberglass fabric is gaining popularity for use in fireproofing applications. It is used in heat shields, fire blankets, and protective clothing, offering excellent protection against high-temperature environments and flames.

Durability and Longevity: Aluminized fiberglass fabric is known for its durability and long service life. It is resistant to abrasion, chemical exposure, and extreme weather conditions, making it suitable for heavy-duty applications, such as exhaust systems, industrial insulation, and welding blankets.

Lightweight and Flexible Solutions: There is a growing demand for lightweight, flexible materials that offer both thermal protection and ease of use. Aluminized fiberglass fabric provides these benefits, making it ideal for applications where flexibility is important, such as in protective covers, industrial gaskets, and automotive components.

Cost-Effectiveness: Aluminized fiberglass fabric remains a cost-effective solution for industries requiring high-performance heat protection. It offers excellent thermal insulation at a lower cost compared to advanced materials like ceramic fabrics, providing a more affordable option for a wide range of applications.

Customization for Specific Applications: The trend toward more specialized solutions is driving the demand for customized aluminized fiberglass fabrics. Manufacturers offer various thicknesses, sizes, and finishes to meet the specific needs of industries such as automotive, energy, and construction.

Sustainability and Eco-Friendly Focus: As industries become more environmentally conscious, aluminized fiberglass fabric is increasingly valued for its sustainability. It is non-toxic, reusable, and recyclable, making it an eco-friendly alternative to some synthetic insulation materials.

Expanding Use in Renewable Energy: The renewable energy sector is adopting aluminized fiberglass fabric for insulation in applications like solar power systems, wind turbines, and geothermal energy, where it provides heat protection in harsh environments.

These trends indicate that aluminized fiberglass fabric is becoming a critical material in industries requiring high-performance, durable, and cost-effective heat protection solutions.