#Product Trends

Can Woven Silica Fabric Withstand Continuous Exposure to High-Heat?

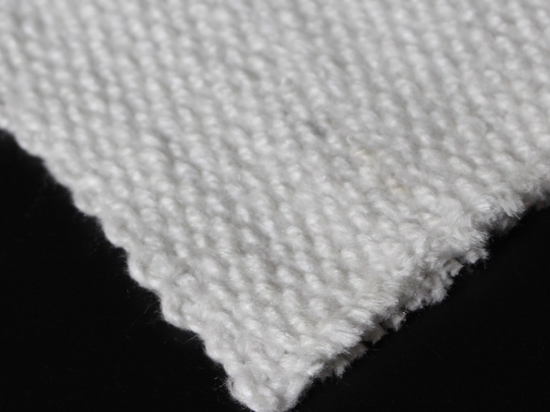

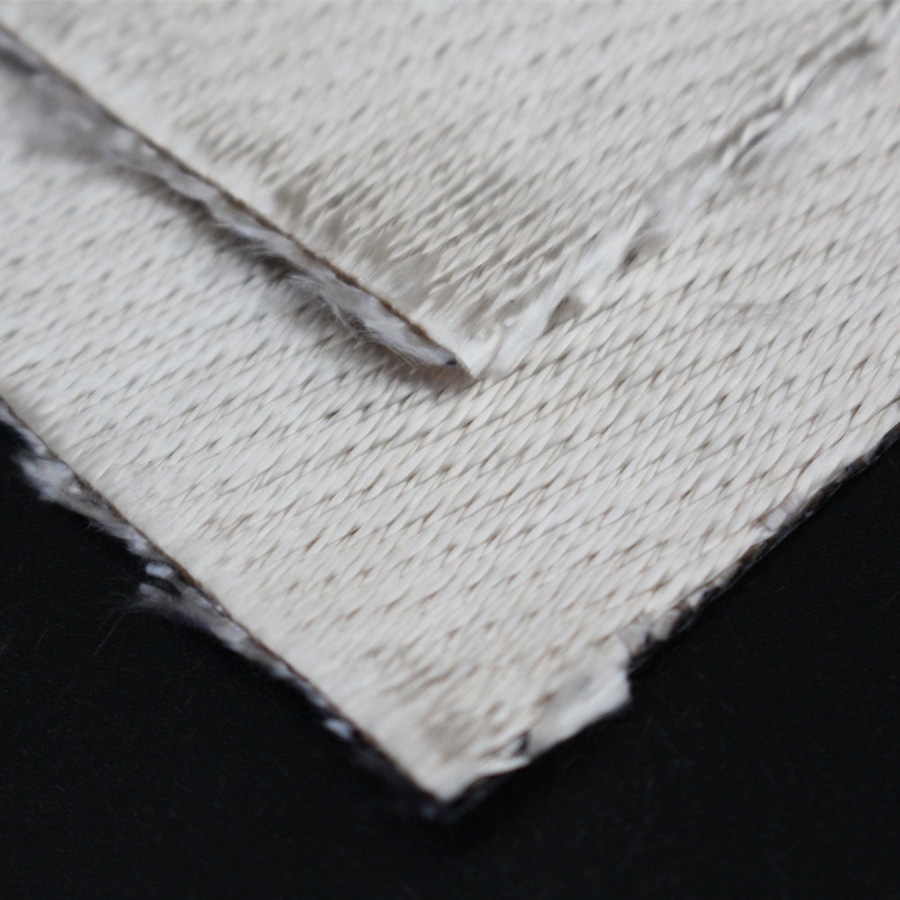

Woven Silica Fabric

Yes, woven silica fabric is specifically designed to withstand continuous exposure to high temperatures, making it an ideal material for long-term heat management in a wide range of industries. Its exceptional thermal stability and ability to retain its strength and shape under extreme conditions set it apart from other heat-resistant materials, ensuring consistent performance over time.

1. Superior High-Temperature Endurance

Woven silica fabric can endure temperatures of up to 1,800°F (982°C) without degradation. Unlike many other heat-resistant materials that lose their insulating properties or structural integrity after prolonged exposure to high heat, silica fabric continues to perform reliably. This makes it an ideal choice for applications where continuous high-heat exposure is a factor, such as industrial furnaces, exhaust systems, and welding environments.

2. Long-Term Durability in Harsh Environments

One of the major benefits of woven silica fabric is its ability to maintain its integrity even after prolonged use in harsh, high-heat environments. Whether used in power plants, petrochemical refineries, or heavy manufacturing, silica fabric’s durability ensures that it will continue to provide reliable insulation and protection throughout the lifespan of the equipment or system. Over time, it won't crack, degrade, or lose its insulating properties, minimizing the need for frequent replacements or repairs.

3. Effective Insulation for Critical Infrastructure

Woven silica fabric is widely used to insulate pipes, cables, and machinery in industries where high temperatures are part of daily operations. In power plants, for instance, silica fabric is used to protect steam pipes, turbines, and cables from the extreme heat generated during electricity production. In petrochemical refineries, it shields sensitive equipment from the high temperatures found in reactors and furnaces. By preventing heat transfer, it improves energy efficiency and reduces the risk of damage to vital components.

4. Applications Across Key Industries

Power Plants: Silica fabric is commonly used to insulate steam pipes and electrical cables, preventing energy loss and protecting vital equipment from heat-induced wear and tear.

Petrochemical Industry: Woven silica fabric shields pipelines, valves, and machinery in environments exposed to constant high temperatures, ensuring uninterrupted performance and reducing the likelihood of downtime or failures.

Welding and Foundries: In welding environments, silica fabric is used to protect workers and equipment from extreme heat, sparks, and molten metal, maintaining safety and efficiency over long shifts.

5. Reduced Maintenance and Downtime

By withstanding continuous exposure to high temperatures without degrading, woven silica fabric significantly reduces the need for maintenance and system downtime. Its ability to retain its performance properties for extended periods translates into lower operational costs, less frequent part replacements, and fewer disruptions to industrial operations. This makes it a cost-effective and reliable solution for long-running industrial processes.