#Industry News

Odot remote IO application case in photovoltaic industry

Silicon material cleaning is an indispensable part in the process of preparing high-purity polysilicon material.

Its main function is to clean away the pollutants, metal ions, oxides, etc. attached to the surface of the silicon material to ensure the cleanliness of the silicon material surface. This process requires a high level of automation. At present, most photovoltaic companies have introduced fully automatic silicon material cleaning machines to ensure the quality of silicon materials and improve production efficiency.

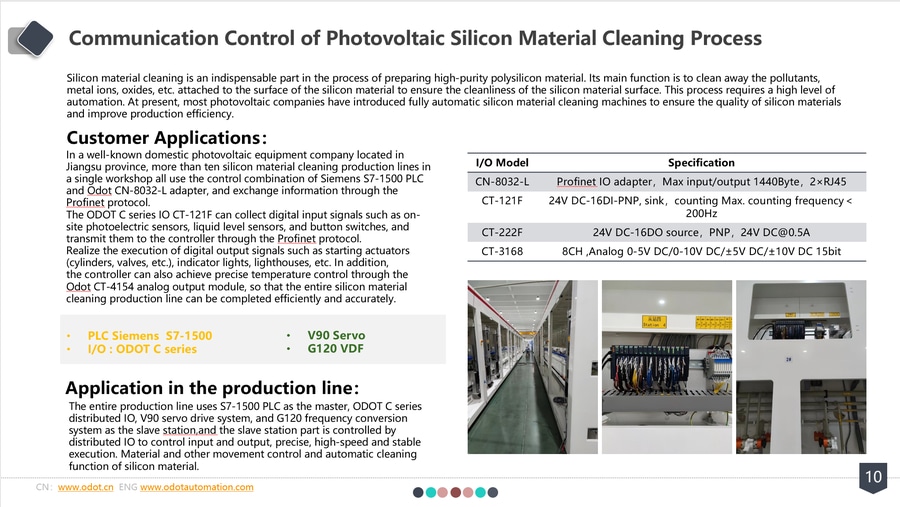

In a well-known domestic photovoltaic equipment company located in Jiangsu province, more than ten silicon material cleaning production lines in a single workshop all use the control combination of Siemens S7-1500 PLC and Odot CN-8032-L adapter, and exchange information through the Profinet protocol.

The ODOT C series IO CT-121F can collect digital input signals such as on-site photoelectric sensors, liquid level sensors, and button switches, and transmit them to the controller through the Profinet protocol.

Realize the execution of digital output signals such as starting actuators (cylinders, valves, etc.), indicator lights, lighthouses, etc. In addition,

the controller can also achieve precise temperature control through the Odot CT-4154 analog output module, so that the entire silicon material cleaning production line can be completed efficiently and accurately.